A great Canadian success story you should know about: A brief look at the National Research Council of Canada flight impact simulators donated to the Canada Aviation and Space Museum, Part 2

Good day to you, my assiduous reading friend. Are you ready to drink from the fount of knowledge otherwise known as our blog / bulletin / thingee? Good for you. Let us continue our investigation of the bird impact research work done in Ottawa, Ontario, by the National Research Council of Canada (NRC).

To do that, we will have to put on our seven decade boots, our nine decade boots actually, and travel back in time to the year 1930.

The Engine Laboratory of the Division of Mechanical Engineering of NRC came into existence that year. One of its very first employees, indeed its first head, was none other than Malcolm Sheraton “Mike / Mac” Kuhring, the very gentleman we encountered in the first part of this article.

In its early days, the Engine Laboratory tested aircraft engines and determined the characteristics of various types of gasoline. That particular line of work took so much time that a separate laboratory was set up for that purpose in 1937. The start of the Second World War, in September 1939, led to a huge increase in the amount of work done. After all, the Engine Laboratory was the one research facility of its type in the country.

For all intent and purposes, it helped the Royal Canadian Air Force (RCAF) stay in the air. That collaboration included both combats units and the multitude of flying schools scattered across Canada under the guise of the British Commonwealth Air Training Plan. A purpose-designed engine testing building was built and later expanded to help with that. Construction may, I repeat may, have begun in 1940, with the first engine test taking place in January 1942. Anxious to have access to a test bed capable of receiving very high-powered engines, the Division of Mechanical Engineering of NRC supervised the construction of equipment which went into service in early 1945.

Some of the wartime work involved checking if American-made cylinders could be used on worn out British-made air-cooled radial engines. They apparently could. Similar tests were conducted to see if American components could be used on British-made liquid-cooled Vee engines. They apparently could.

The Engine Laboratory also certified a Canadian-made but American-designed propeller used on training aircraft.

Yours truly wonders if that propeller could be the so-called Hoover propeller.

From 1941 onward, one of the largest, if not the largest manufacturer of railway rolling stock in Canada, Canadian Car & Foundry Company Limited (CCF) of Montréal, Québec, and elsewhere in Canada, a firm mentioned several times in our blog / bulletin / thingee since October 2018, began to produce propellers. It had acquired the license of a two-blade propeller from Walter Scott Hoover, an American engineer who was seemingly not related to the people who ran the American home appliance giant Hoover Company.

CCF assembled the mechanisms manufactured in one of its factories, in Montréal, and added to it blades made of aluminum and, later on, wood. The latter were produced by Singer Manufacturing Company Limited, the Canadian subsidiary of a well-known American sewing machine manufacturer, Singer Manufacturing Company, at its factory in Thurso, Québec.

Used on advanced training aircraft, the Hoover propeller may unfortunately not have been completely reliable.

Mind you, Singer Manufacturing also produced wooden blades mounted on propellers designed and manufactured by the British firm Rotol Airscrews Limited. These propellers were themselves mounted on Hawker Hurricane fighter planes built by CCF in Fort William, Ontario, and subsequently delivered to the Royal Air Force and RCAF.

Now, do you know which internationally-known aviation museum has a Hurricane in its collection? The Canada Aviation and Space Museum in Ottawa, Ontario, you say? Good answer. Your brown envelope will ready by the end of the day.

Naturally enough, the Engine Laboratory of NRC was involved in cold weather testing of engines. It also did a lot of work on the engines of ground vehicles operated by the Canadian Army.

As we both know, cognescentis that we are, the Second World War saw the introduction of a revolutionary new type of aeroengine, the jet engine. From 1946 onward, the Engine Laboratory saw its work switch for piston engines to jet engines. Indeed, by 1950, it spent almost all its time conducting research on the low temperature operations of such engines, especially issues connected to icing. Much of that was done at a cold weather test station set up in Manitoba during the conflict.

Following in the footsteps of work done in the United Kingdom and United States, some of the work the Engine Laboratory conducted involved the development of an afterburner / reheat mounted at the rear of a jet engine. Fuel injected in that tube was ignited by the very hot exhaust gases rushing out of the engine, greatly increasing thrust – and fuel consumption. That afterburner was later tested on a suitably modified Canadair Sabre, a license-made version of the American North American F-86 Sabre fighter plane.

And yes, I do realise that this turn of phrase is a tad confusing. Were you confused?

Good for you.

Following in the footsteps of work done in the United Kingdom and United States, the Engine Laboratory also investigated the idea of injecting water in a jet engine to reduce internal temperature and allow for an increase in thrust.

Interestingly enough, the staff also developed a semi-diesel engine for use on small fishing boats. Whether or not that engine was put in production is unclear. Sadly, I doubt it was.

And yes, the mind blowing collection of the Canada Aviation and Space Museum includes a Canadair-made Sabre.

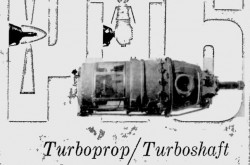

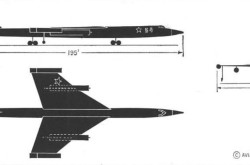

Mind you, the Engine Laboratory also conducted research on the effects of foreign object ingestions on jet engines. Indeed, that work helps to explain why it became involved in bird strike research. Indeed, again, as will be seen (read?) below, the Engine Laboratory developed the first flight impact simulators put together in Canada:

- the EL-1, with a 19-millimetre (0.75 inch) barrel,

- the EL-2, with a 76-millimetre (3 inches) barrel, maybe, and

- the EL-3, with a 95-millimetre (3.75 inches) barrel initially and an 89-millimetre (3.5 inches) barrel later on.

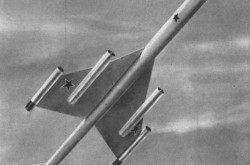

In the 1960s and later, the Engine Laboratory spent a great deal of time and effort on the application of jet engines to vertical take off and landing (VTOL) aircraft – a type of machine then very popular with military operators. It also conducted research on the aerodynamics of the flow of air within certain type of gas turbine compressors. That work resulted from a renewed interest in small gas turbines that could be used in automobiles or light / private planes.

And no, my sometimes over enthusiastic reading friend, the Hawker Siddeley AV-8A Harrier on display at the Canada Aviation and Space Museum does not belong to that fabulous museal institution. That British VTOL ground attack aircraft actually still belongs to the United States Navy.

The Engine Laboratory became part of the Structures, Materials and Propulsion Laboratory of the Institute for Aerospace Research of NRC in the 1990s. That laboratory was split later on to create a Structures and Materials Performance Laboratory and a Gas Turbine Laboratory. Both of these laboratories may still exist in 2022, in some form or other, as part of NRC’s Aerospace Research Centre.

If yours truly may be permitted to paraphrase the great Canadian television host Elwy McMurran Yost, now it is that time, my reading friend, time to turn your lights down low and put your feet up. Time to learn about the saga of one of the flight impact simulators donated to the Canada Aviation and Space Museum.

Incidentally, did you know that Yost worked in the personnel department of Canadian aeronautical giant A.V. Roe Canada Limited (Avro Canada) of Malton, Ontario, between 1953 and 1959? And yes, Avro Canada was mentioned many times in our blog / bulletin / thingee, and this since March 2018.

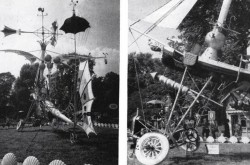

The story of the aforementioned flight impact simulators donated to the Canada Aviation and Space Museum actually began with a compressed air gun which may never have been used to test aircraft components. Indeed, the first compressed air gun made in Canada, in late 1964 or early 1965, may have been some sort of pilot model. Built in-house by the Engine Laboratory, the EL-1 had a 3.65-metre (12 feet) long barrel and a 19-millimetre (0.75 inch) bore. Also known as the 0.75-inch gun, that device could fire a projectile at speeds of up to 875 kilometres/hour (540 miles/hour). It was put together to initiate the study of bird and hail impact on aircraft structures in Canada.

It is possible that a second flight impact simulator, the EL-2, was operated using a new barrel with a 76-millimetre (3 inches) bore, and that perhaps in conjunction with the compressed air reservoir of the EL-1.

Neither the EL-1 nor the EL-2 still exist. Pity.

By the end of 1965, a third flight impact simulator, the EL-3, also developed by the Engine Laboratory, was in operation. It used the reservoir of its predecessors. That device was Canada’s first fully functional flight impact simulator. Also known, in its early days, as the 3.75-inch gun, it had a 3.65-metre (12 feet) long barrel and a 95-millimetre (3.75 inches) bore. That device could fire fully feathered birds weighing up to about 900 grammes (2 pounds).

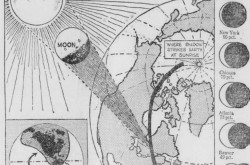

The 3.75-inch gun was apparently built to conduct impact tests on the tailplane / tail assembly of the Vickers Viscount turboprop airliner, a type of aircraft operated by Trans-Canada Air Lines / Air Canada and numerous other airlines around the world. You may wish to note that what follows is very disturbing.

The reason behind the interest of the Engine Laboratory was the crash of a Viscount of an American air carrier in November 1962. As it flew over Maryland at an altitude of about 1 800 metres (about 6 000 feet), the airliner ran into a flock of migrating swans. One of the two birds which hit it damaged the port / left horizontal stabiliser to such an extent that the latter quickly broke off. The crew lost control of the aircraft. The Viscount fell west of Baltimore, Maryland. All 17 people on board died. That tragedy was instrumental in pushing through a requirement that the tailplane / tail assembly of airliners be able to resist the impact of an 3.6-kilogramme (8 pounds) bird.

And yes, my shocked reading friend, there is a Viscount in the collection of the Canada Aviation and Space Museum. Incidentally, the Viscount was a very successful and robust airliner. Like other airliners of its day, it simply had not been designed to resist a direct hit on its tailplane / tail assembly by a bird as large as a swan.

The basic operating principle of 3.75-inch gun was quite simple. A fully feathered bird was put in a cardboard and polystyrene foam container, or sabot, prior to firing. That sabot prevented the loss of air pressure before the bird left the barrel, and helped to keep it intact during acceleration.

The idea of using a sabot presumably came as a result of discussions with staff members of the Royal Aircraft Establishment, in England, which had commissioned a sizeable flight impact simulator in 1961. After all, it was in England that the sabot was perfected, during the Second World War, by the Armaments Research Department of the Ministry of Supply.

The researchers were then looking for a better way to destroy German main battle tanks. They had recently developed a new type of projectile with a lightweight (aluminium and steel?) body, and a core made of tungsten carbide – a heavy, almost diamond-hard material. That Armour-Piercing Composite Rigid shot or High-Velocity Armour-Piercing shot, as the Americans called that type of projectile, proved deadly at close range but its speed and armour piercing capabilities quickly went down as range increased.

The solution the British researchers came up with was the Armour-Piercing Discarding Sabot (APDS) shot, which surrounded the tungsten carbide core with a lightweight body that fell away as the shot came out of the barrel of an anti-tank gun. The fast moving tungsten carbide core proved capable of punching through the armour of German main battle tanks both near and far. Greatly improved over the years, the APDS was one of the main tank-killing projectiles fired by Cold War era main battle tanks.

The French firm Établissements Edgar Brandt Société anonyme seemingly developed early versions of the APCR or APDS projectiles before the Second World War. To a point, these projectiles may, I repeat may, have served as the basis for the work done in England, but back to our story.

Ah yes, one more thing before I forget. The 3.75-inch gun was kept in a building at all times.

In late 1971, the 3.75-inch gun came to the Structures and Materials Laboratory of the National Aeronautical Establishment (NAE), an independent division of NRC based in Ottawa, with facilities at Uplands, near Ottawa. Formed in 1951 as an arm of NRC’s Division of Mechanical Engineering, the NAE had become an independent entity in 1959.

In late 1971 or early 1972, the 3.75-inch gun was fitted with a new 3.65-metre (12 feet) long barrel with an 89-millimetre (3.5 inches) bore. It was known from then on as the 3.5-in gun. And yes, it was also kept in a building at all times.

It was in 1972 that the 3.5-inch gun joined the much larger 10-inch gun mentioned in the third part of this article.

Little information has come to light concerning the work done with the 3.75- / 3.5-in gun before 1972. This being said (typed?), it looked as if it fired pigeons and ground beef, a bird substitute, at various targets, one of these being the windshield of one or more Avro Canada CF-100 Canuck all weather bomber interceptors, an aircraft type present in the mind-blowing collection of the Canada Aviation and Space Museum.

The 3.75- / 3.5-inch gun was also used to test the housings of cardiac pacemakers seemingly put on the market in Europe in 1970 by a West German firm, Biotronik Gesellschaft mit beschränkter Haftung & Compagnie Kommanditgesellschaft. Said cardiac pacemakers were fitted with a Betacel beta voltaic battery developed by Donald W. Douglas Laboratories, a division / department of McDonnell Douglas Corporation, an American aerospace giant mentioned in a March 2018 issue of our blog / bulletin / thingee.

Such batteries produced electricity via the decay of a radioactive isotope, yes, yes, radioactive, known as promethium-147. I kid you not.

And here is a cutaway drawing of the pacemaker in question.

A cutaway drawing of a Biotronik pacemaker powered by a Betacel beta voltaic battery. Tom Rigert, “Nuclear pacemaker inserts possible in Tri-City hospitals.” Tri-City Herald, 20 February 1973, 4.

And no, yours truly does not quite know how big the actual pacemaker in question was.

At least one model of Biotronik Betacel pacemaker was expected to keep on going for up to 10 years, when the battery ran out of power and the pacemaker itself had to be replaced. By comparison, the battery of a conventional pacemaker of the time had to be replaced every 2 years. And yes, that meant surgery, but back to the tests conducted with the Canadian flight impact simulator.

Said tests came as a result of concerns regarding the release of radioactive material, toxic material let us not forget, during automobile and / or aircraft accidents involving wearers of “nuclear-powered” pacemakers.

In the end, relatively few Biotronik Betacel pacemakers were put into patients. You see, power outputs dropped by 50 % within 2.6 or so years of insertion. That 50 % power output left was cut in half after another 2.6 or so years, and so on. And yes, my mathematically astute reading friend, about 10.5 years after installation, a Biotronik Betacel produced 6.25 % of the power generated when it was put in a chest.

If I may be to go techie for a few billion nanoseconds, promethium-147 had / has a half life of about 2.6 years.

Speaking (typing?) of half life, would you believe that this was how Herbert George “H.G. Wells” imagined the “atomic bombs” of The World Set Free, a 1914 apocalyptic novel published just before the onset of an apocalyptic conflict, the First World War, would work? And yes, it was Wells who first used the expression “atomic bomb.”

The lethal ingredient of said bombs, a fictitious element known as Carolinum, had a half-life of 17 days, which meant that each bomb “poured out half the huge store of energy in its great molecules in the space of seventeen days, the next seventeen days’ emission was half of that first period’s outpouring and so on….” Depending on the size of the bomb, that outpouring could continue for weeks, months or even years.

Wells, a world famous British writer and science fiction pioneer mentioned many times in our equally famous blog / bulletin / thingee and that since November 2018, did not initiate the fictional use of nuclear weapons, however. Nay. In 1911, The Lord of Labour, a novel published soon after the death of its author, British explorer, journalist and writer George Griffith, born George Chetwynd Griffith-Jones, offered to its readers the first depiction of atomic projectiles, in that case small devices fired from portable launchers.

The first description of a nuclear weapon, built by an evil scientist who then blackmailed the world, could be found in a little known work. Irish author and journalist Robert Cromie published The Crack of Doom in 1895. That date of publication was / is particularly interesting, at least for me.

You see, my reading friend, the French physicist Antoine Henri Becquerel discovered that a material known as uranium emitted some sort of energy, a characteristic soon christened radioactivity, in… 1896. Before that date, the idea that the energy inside the atoms that make up our world could be used for good, or evil, was pretty much unheard of. Who knows how Cromie came up with his nuclear weapon idea.

And yes, Becquerel, Cromie and Griffith were all mentioned in a December 2018 issue of our you know what. Indeed, the lazy bum that I am pretty much copied word for word the lines of text dealing with these gentlemen contained in said issue and pasted them in the issue you are reading now, but back to the Biotronik Betacel pacemaker.

As you may well imagine, a few / several / many / most potential individuals in need of a pacemaker were not exactly thrilled at the idea of carrying radioactive material in their chest cavity. That wariness led to the commercial failure of the Biotronik Betacel pacemaker. Well, that and the introduction of long lasting and cheaper lithium-ion batteries, in the late 1970s.

By the way, did you know that pacemakers whose battery was powered by plutonium were put into patients? I kid you not. By plutonium, the very element used to power (thermo)nuclear weapons during the Cold War. Work on that pacemaker project began in the mid 1960s. The first nuclear-powered pacemaker was actually powered by a tiny piece of plutonium. It was put in a patient in Paris, France, in April 1970. Several / many firms in France, the Union of Soviet Socialist Republics, the United States, West Germany (?) and quite possibly elsewhere eventually produced such devices.

Plutonium, a highly toxic material, far worse than promethium, has a half life of 88 years, which meant that a patient did not have to worry about the power level of the battery in his or her chest. Mind you, when an American patient left this world, the pacemaker was supposed to be removed and shipped to the Los Alamos National Laboratory, in New Mexico, where the plutonium was recovered. One presumes that other countries proceeded in a similar fashion.

And yes, there are probably many people going about their daily business, especially / primarily in the Russian Federation, thanks to the power produced by the plutonium in their chest. They may keep on going for years to come. You see, the last Soviet patient fitted with a plutonium-powered pacemaker seemingly left a hospital in the mid-1980s.

Apologies for the length of this digression but I found the idea of a nuclear-powered pacemaker simply irresistible, if I may be permitted to quote the title of the eponymous 1988 hit song by the English musician, singer and songwriter Robert Allen Palmer, but back to our chicken.

The 3.5-inch gun also fired dummy 20-millimetre (0.8 inch) shells and 25-millimetre (1 inch) steel balls at military aircraft windshields in order to improve their design. The main threats here were presumably anti-aircraft projectiles and fragments thereof rather than birds.

Toward the end of its career, the 3.5-inch gun fired fully feathered birds into running jet engines as well as human-made hailstones at panels made of composite materials. By and large, these particular tests were conducted on behalf of foreign customers.

The 3.5-inch gun also played a limited role in the development of the two modern flight impact simulators put in service in 1998 and 2011 by the aforementioned Institute for Aerospace Research. And yes, these devices were indeed mentioned in the first part of this article.

The 3.5-inch gun is the oldest surviving flight impact simulator in the world. It was officially retired in 2010, after 45 years of service. The Canada Aviation and Space Museum officially acquired it in December 2012.

Yours truly hopes to meet you again next week, so that we can go over the saga of the other flight impact simulator of the Canada Aviation and Space Museum.

![A block of photographs showing some of the people involved in the bombing of beluga whales in the estuary and gulf of the St. Lawrence River. Anon., “La chasse aux marsouins [sic]. » Le Devoir, 15 August 1929, 6.](/sites/default/files/styles/thumbnail_7/public/2024-09/Le%20Devoir%2015%20aout%201929%20page%206.jpg?h=584f1d27&itok=TppdLItg)

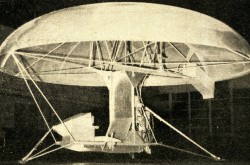

![Peter Müller at the controls [sic] of the Pedroplan, Berlin, Germany, March 1931. Anon., “Cologne contre Marseille – Le mystère du ‘Pédroplan.’ [sic]” Les Ailes, 2 April 1931, 14.](/sites/default/files/styles/thumbnail_7/public/2021-04/Les%20Ailes%202%20avril%201931%20version%20big.jpg?h=eafd0ed4&itok=WnBZ5gMf)

![One of the first de Havilland Canada Chipmunk imported to the United Kingdom. Anon., “De Havilland [Canada] DHC-1 ‘Chipmunk.’” Aviation Magazine, 1 January 1951, cover.](/sites/default/files/styles/thumbnail_7/public/2021-01/Aviation%20magazine%201er%20janvier%201951%20version%202.jpg?h=2f876e0f&itok=DM4JHe5C)