Weed’em and Reap: Leavens Brothers Air Services Limited and the early days of agricultural aviation in Ontario / Canada after the Second World War

Are you a vegetarian, my reading friend, or a vegan? Omnivore, perhaps? Or frutarian, lacto-vegetarian, ovo-vegetarian, lacto-ovo-vegetarian? No matter.

For thousands of years, people all over our spherical, yes, yes spherical, planet have depended on the crops they grew to sustain them. Agriculture, as you undoubtedly know, appeared about 12 000 years ago in a region of the Earth known as the Fertile Crescent, a crescent region anchored on the Nile, in modern day Egypt, at one end, and on the Tigris and Euphrates, 2 rivers in modern day Iraq, at the other.

Throughout that time, however, humans had to battle a host of natural enemies in order to protect these vital food supplies. These foes were mostly of 3 types: insects and their kin, weeds, and diseases.

Such assaults were not limited to the distant past. There was a major outbreak of grasshoppers in Alberta and Saskatchewan as recently as the 1930s when these insects swarmed in countless numbers, eating whatever crops had not been destroyed by the drought which afflicted these Canadian provinces during that decade. The only weapon available against these ravenous insects was ground-spread poison bait and it proved only moderately effective. Farmers and entomologists knew that Mother Nature was still their best ally in pest control, and that natural predators, parasites and bad weather were the best killers of insects like grasshoppers.

Even today, in 2020, in North America, one of the wealthiest regions of the world, insects and their kin, weeds, and diseases still pose a formidable problem. This being said (typed?), a formidable if controversial weapon now exists to battle these foes, namely agricultural aviation.

A definition of what is meant by agricultural aviation or, as it is also called, aerial application, agro-aeronautics or ag flying, would be useful before we go any further. Even though it covers a wide range of activities, from spreading seeds or toxic chemicals on fields to flying through citrus groves to stir the air when freezing weather threatens, agricultural aviation’s main objectives lie in providing pest control and / or nourishment for both food and commercial crops. This can be done through either dusting with fine powders or spraying with minute droplets.

Top dressing, the spreading of fertiliser over large areas to help feed cattle and sheep, may or may not fall within the purview of agricultural aviation. Many authors deem it closer to ranching than agriculture. It follows that the protection of forests, through forestry aviation, is also beyond the purview of agricultural aviation. Unlike agricultural aviation, forestry aviation is mainly crisis-oriented rather than operated on a predictable and recurring basis.

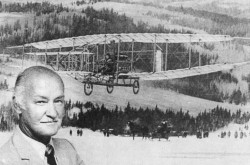

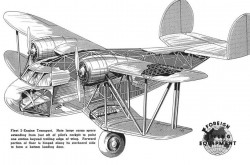

Even though the idea of using a flying machine to apply toxic chemicals to control pests of various types predates the First World War, agricultural aviation actually emerged after the conflict, in the United States. The first well documented demonstration took place in August 1921. A plague of leaf-eating caterpillars was then devastating trees in Troy, near Dayton, Ohio. The United States Army Air Service (USAAS) provided a single Curtiss JN-6 training airplane with minimal modifications to the airframe. In spite of this rather primitive equipment, the results of this crop dusting experiment were deemed satisfactory.

The JN-6 was, of course, closely related to the Curtiss JN-4 Canuck, an aircraft found in the monumental, nay, phenomenal collection of the Canada Aviation and Space Museum, in Ottawa, Ontario.

The success of a crop dusting trial organised in Louisiana in the summer of 1922 by a cotton research station of the United States Department of Agriculture, with the assistance of 2 JN-6s provided by the USAAS, helped to convince the sceptics that aerial application would lead to substantial savings in labour, money, and time.

The first aerial application firm in the world, Huff Daland Dusters Incorporated, a subsidiary of the American aircraft manufacturing firm Huff, Daland & Company and the ancestor of today’s Delta Air Lines Incorporated, was established in March 1925, signalling the beginning of a new industry.

In Canada, the federal Department of Agriculture was the driving force behind the early use of aerial application. Although reluctant to spend part of its limited acquisition budget (Hello, EG!) on non-military aircraft, the Royal Canadian Air Force (RCAF) purchased a pair of Huff Daland Dusters single-engined biplanes, a type also known as the Keystone Puffer, in March 1927.

From 1927 until 1931, when it stored the surviving machine, the RCAF used the Dusters / Puffers for a series of wheat field and forest dusting trials. The former took place in southern Manitoba. Although extremely enlightening from the point of view of the Department of Agriculture, the dusting program was only modestly successful in combating pests.

Even though a few people organised other experiments in Alberta, including poisoned bait spreading to combat grasshoppers, the many difficulties caused by the Great Depression of the 1930s made the establishment of commercial aerial application companies in Canada very difficult.

In early September 1939, the Second World War began, which meant that research was halted until the end of the conflict.

The postwar era of agricultural aviation in Canada began in May 1945. A pea aphid outbreak was hitting some farms located near Essex, near Windsor, Ontario. Faced with the need for quick action, farmers contacted Leavens Brothers Air Services Limited, a well-known and respected general aviation firm founded in 1927 by brothers Clarence Roswell “Clare” Leavens, David Arthur “Art” Leavens and Walter Thomas “Walt” Leavens. Intrigued by the request, the Toronto-based firm fitted one of its machines, its sole Piper J-5 Cub Cruiser light / private airplane, with a funnel-shaped aluminum alloy hopper of unknown origin (designed in house? bought?). Installed behind the pilot’s seat, this hopper could hold up to 135 kilograms (300 pounds) of toxic powder.

A rotating agitator was used to make sure that this powder would not pack down at the bottom of the hopper. To operate this agitator, a wheel with 4 wind cups was mounted outside the fuselage of the airplane, on the port / left side. A chain drive, rather similar in appearance to that of a common bicycle, linked the wheel to the agitator. There was a valve at the bottom of the hopper which regulated the toxic powder’s flow. A small plate mounted beneath the airplane’s fuselage, below the valve, formed a primitive venturi which broke up the powder and formed the cloud needed to kill the insects.

The dusting of crops required special flying techniques since the airplane spent most of its time just 1.5 to 2 metres (5 or 6 feet) above the ground. Weather conditions had to be just right to do the job properly and reduce the risks of accident caused by turbulence. The Cub Cruiser often flew during the hour after dawn, for example. There was hardly any wind and the dew, still present on the crop, helped to keep the powder on both surfaces of the plants’ leaves.

Representatives from Canadian Industries Limited, which had supplied the insecticide, as well as the director of the Dominion Entomological Laboratory, in Chatham, Ontario, Dr. George M. Stirrett, were on hand to watch the trials, which began in May and may have continued into July. Overall, the results of this experimental program were quite satisfactory. Indeed, they convinced the management at Leavens Brothers Air Services that aerial application had a future in Canada.

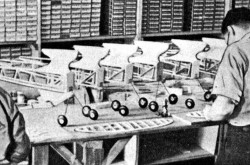

Despite the number of obstacles and the small size of the average field in southern Ontario, Leavens Brothers Air Services did not consider that a brand new type of flying machine, the helicopter, was the way to go. A suitably-modified light / private airplane like its Cub Cruiser, on the other hand, could become a fairly important tool, if the results and costs were competitive with those of ground-based machinery. Confident that this could be achieved, the firm had 2 light / private airplanes ready for flight by the spring of 1946.

At the time, however, most southern Ontario farmers remained sceptical. Some way would have to be found to convince them that airplanes could take care of their needs quickly, efficiently and without damage to their crops. An occasion presented itself in early August 1946, when a pair of tobacco growers from the Komoka area, near London, Ontario, contacted Leavens Brothers Air Services. Their crops were in need of dusting. A team was sent. The operation was a success, despite numerous difficulties, and a few contracts soon followed. By the end of 1946, 110 hectares (270 acres) of farmland had been treated. In 1952, by comparison, the firm treated 30 000 hectares (75 000 acres) of farmland.

In the middle of 1952, Leavens Brothers Air Services created Canada’s first school for agricultural pilots, at Crumlin Airport, now London International Airport, near, well, London. It came under the responsibility of the firm’s local branch manager, George E. Walker. Some 12 pilots made up the first class. The week-long course was intensive and tough. Students were taught how to work with toxic chemicals and how to apply them safely and evenly. Both aviation and chemical regulations, use of fields and basic business practices were also part of the curriculum. In the end, half of the pilots enrolled failed. The graduates, some of them hired by Leavens Brothers Air Services, would play their part in reducing the shortage of trained agricultural pilots in Canada. The intent was to reduce the number of accidents by teaching the proper methods of aerial application.

Sadly, yours truly was unable to find out how long the school lasted. Somehow, I have a feeling it may not have lasted very long.

Throughout that period, Leavens Brothers Air Services gradually improved its dusting equipment. For example, the many corners and ledges in the hoppers of the airplanes were eliminated to improve the flow of the toxic powder. Venturies were redesigned and fitted with ribs, thus ensuring a better distribution. A new material replaced wood in hopper gates, which used to leak and cause problems in wet weather. In addition, the amount of toxic powder entering the airplanes’ cockpit was reduced by various means.

Methods of application were also improved. For example, Leavens Brothers Air Services realized that the amount of filler material could be cut. Thus, rather than 34 kilograms of toxic powder and filler per hectare (30 pounds/acre), the airplanes could use just 22 kilograms per hectare (20 pounds per acre) and be just as effective. This reduced costs and increased by 50% the area each airplane could cover with one load.

By 1948, Leavens Brothers Air Services was conducting aerial spraying experiments, apparently with a suitably-modified Piper light / private airplane. The firm hoped that the lower price of the chemicals used for the spraying mix would lead to a reduction in overall cost when compared with dusting. Any water used to dilute said chemicals would also be pretty well free. Early results were encouraging, especially in the case of crops like corn, onions and tobacco. Leavens Brothers Air Services soon added spraying to the list of services it provided on a regular basis.

Similarly, the firm conducted trials with certain crops using combination powders that provided protection against both insects and disease.

Each dusting and / or spraying crew consisted of 1 or 2 pilots, and 1 ground crewperson, all right, all right, crewman. The latter drove a truck and each pilot flew an airplane. The teams took up residence in the designated area, usually in a tent, in a field belonging to a local farmer. This approach saved a lot of flying time and ensured that the windless hours early in the morning and the evening would be fully used. To save yet more time, the pilots and ground crewmen developed methods by which they were able to load up an airplane in barely 2 minutes.

The teams, supervised by a dusting and / or spraying manager, normally flew inside a 16-kilometre (10-mile) radius around their landing field. Given the importance of good weather conditions for this type of operations, the teams might toil 7 days a week from dawn until dusk. Another incentive for hard work had to do with the fact that all team members were paid on a commission basis. This ensured that everyone worked hard to promote the firm and obtain new contracts.

By the summer of 1953, Leavens Brothers Air Services was dusting and / or spraying a variety of crops: beans, cabbage, carrots, celery, corn, cucumbers, melons, onions, peas and tomatoes, not to mention tobacco and clover. Both insects and plant diseases were controlled from the air. At some point during the 1950s, the firm’s agricultural fleet included 7 Piper type light / private airplanes.

To facilitate picking, Leavens Brothers Air Services sprayed tomato, potato and bean plants with defoliant. As well, the firm was conducting experiments to counteract soil deficiencies, using liquid fertilizers. It was also involved in mosquito control, as well as forest caterpillar and spruce budworm control, and this both in Ontario and Québec.

As time went by, Leavens Brothers Air Services / Leavens Brothers Limited, a corporate name adopted no later than 1956, prospered. For one reason or other, it nonetheless abandoned aerial application in 1958. Another local operator applied for and obtained the operating licence the firm had surrendered.

Based in Mississauga, Ontario, in recent years, Leavens Aviation Limited distributed aircraft parts, overhauled engines and supplied accessories. It also did some manufacturing and sub-contracting. Sadly enough, Leavens Aviation wound up its operations in 2011. It was the end of an era.

Be well, my reading friend, and stay out of trouble. I know you.

![A block of photographs showing some of the people involved in the bombing of beluga whales in the estuary and gulf of the St. Lawrence River. Anon., “La chasse aux marsouins [sic]. » Le Devoir, 15 August 1929, 6.](/sites/default/files/styles/thumbnail_7/public/2024-09/Le%20Devoir%2015%20aout%201929%20page%206.jpg?h=584f1d27&itok=TppdLItg)

![Peter Müller at the controls [sic] of the Pedroplan, Berlin, Germany, March 1931. Anon., “Cologne contre Marseille – Le mystère du ‘Pédroplan.’ [sic]” Les Ailes, 2 April 1931, 14.](/sites/default/files/styles/thumbnail_7/public/2021-04/Les%20Ailes%202%20avril%201931%20version%20big.jpg?h=eafd0ed4&itok=WnBZ5gMf)

![One of the first de Havilland Canada Chipmunk imported to the United Kingdom. Anon., “De Havilland [Canada] DHC-1 ‘Chipmunk.’” Aviation Magazine, 1 January 1951, cover.](/sites/default/files/styles/thumbnail_7/public/2021-01/Aviation%20magazine%201er%20janvier%201951%20version%202.jpg?h=2f876e0f&itok=DM4JHe5C)