A Tamias striatus cavorting in the clouds: The de Havilland Canada Chipmunk

Bienvenue and welcome to the fabulous world of aviation and space. Did you notice that last week’s article in our blog / bulletin / thingee was about an excellent Canadian aircraft, the de Havilland Canada Caribou? Yes? Wunderbar. Are you happy with this choice? Doubly wunderbar.

Having mentioned the name of another aircraft designed by de Havilland Aircraft of Canada Limited (DHC) of Downsview, near Toronto, Ontario, in said article, the idea occurred to me to discuss its story this week. And yes, an example of said aircraft is part of the world class collection of the Canada Aviation and Space Museum in Ottawa, Ontario.

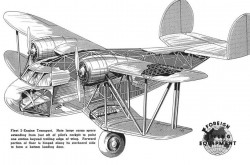

The aircraft in question, the Chipmunk, or “Chippie,” the first aircraft designed by DHC if you must know, has its origins in discussions involving representatives of its British parent company, de Havilland Aircraft Company Limited, which took place in 1945. Armed with the experience gained during the Second World War, the engineers of the Ontario firm wanted to design and manufacture their own aircraft.

Far from opposing this idea, their British counterparts offered some advice. The bushplane market, then under study, was likely to be tight, they believed. That of training aircraft, civilian and / or military, on the other hand, appeared much more promising. An aircraft capable of replacing the de Havilland Tiger Moth initial / elementary / basic training aircraft, which was rather obsolete in 1945, would be welcome. De Havilland Aircraft committed itself to helping its subsidiary bring this new aircraft to market if it proved successful.

And yes, the Tiger Moth was mentioned several / many times in our blog / bulletin / thingee since May 2018. Would you believe that the Canada Aviation and Space Museum’s wunderbarian collection includes a Tiger Moth – a Menasco Moth to be more precise?

Encouraged by the support of its parent company, DHC developed an initial training aircraft – a type of aircraft which was technically uncomplicated but still very important. A brilliant Polish engineer who had come to Canada during the Second World War, Wsiewołod Jan “Jaki” Jakimiuk, mentioned in a February 2018 issue of our you know what, led the design team.

Jakimiuk was not some unknown guy. He was in fact the former chief engineer of the state-owned firm Państowe Zakłady Lotnicze (PZL), the most important Polish aircraft manufacturer of the interwar period.

The first Chipmunk flew in May 1946, less than a year after the project began. It was the first all-metal aircraft designed by the Ontario firm – and one of the first designed by de Havilland Aircraft or one of its subsidiaries.

The Chipmunk apparently got its name following a suggestion made by DHC’s general manager Phillip Clarke Garratt, amused by cavorting chipmunks near his cottage.

Several foreign civilian and military customers quickly took an interest in this excellent two-seater. In 1948, for example, DHC signed its first major contract, with the Indian Directorate General of Civil Aviation which, following the country’s independence, sought to increase the number of civilian pilots and instructors. The Toronto aircraft manufacturer shipped 40 or so Chipmunks to India.

Over the months, the aircraft manufacturer received a few more orders from abroad.

While the Royal Canadian Air Force (RCAF) ordered 4 Chipmunks in 1948, 3 of which were used for the training of observation pilots, the fact was that this service was not overly interested in this aircraft. At that time, it used a much more powerful and complex machine, a machine mentioned in May 2019 issues of our blog / bulletin / thingee, the North American Harvard, to train its pilots.

This being said (typed?), the RCAF realised the importance of maintaining the skill level of its reservists. In 1950, it launched a Refresher Flying Training Plan. A federal agency usually linked to exports, the Canadian Commercial Corporation, purchased 45 Chipmunks and turned them over to the Department of National Defence. The latter then loaned these aircraft to the 20 or so flying clubs participating in the program.

It should be noted that the tandem arrangement of the Chipmunk’s seats did not necessarily appeal to said flying clubs, who preferred to use aircraft with side-by-side seats. The Chipmunk was also more expensive than most of the light / private aircraft they commonly used.

Interestingly, it is possible that, around 1945-47, DHC considered the possibility of developing a derivative of Chipmunk with side-by-side seats.

The RCAF took delivery of 5 Chipmunks in 1952 to study a training formula which included a few flights on a light aircraft. Satisfied with the results of these tests, completed in 1954, it wanted to order 35 Chipmunks. DHC, which did not produce the aircraft at that time, requested that this total be increased to 60.

Somewhat surprised by this request, the RCAF decided to get rid of the 25 Beech Mentors it had just purchased. Now short of initial training aircraft, this service could ask the Department of Defence Production to order 60 Chipmunks. A strike which affected the DHC workshops between the end of June and the middle of November 1955 delayed the delivery of these aircraft, however.

Over the years, the RCAF thus received approximately 120 Chipmunks.

If I may be permitted a brief digression, the Mentors, American-designed aircraft made under license by Canadian Car & Foundry Company Limited, a firm mentioned in May 2019 and July 2020 issues of our blog / bulletin / thingee, were quickly given to the Ellinikí Vasilikí Aeroporia and the Türk Hava Kuvetleri, the air forces of 2 member countries of the North Atlantic Treaty Organization (NATO), Greece and Turkey.

DHC exported about 40 Chipmunks intended for the air forces of 2 countries in Africa (Egypt) and Asia (Thailand).

The Thai government actually considered the possibility of acquiring the production rights for the aircraft in 1949 but ended up abandoning the project.

It should be noted in passing that the Force aérienne belge / Belgische Luchtmacht acquired 2 Chipmunks for evaluation purposes. It ultimately decided to order a Belgian aircraft.

A little more than 215 Chipmunk left the workshops of DHC between 1946 and 1956.

The success of the Canadian initial training aircraft did not end there, however. Nay. In the spring of 1948, for example, DHC granted the license for the Chipmunk to its British parent company, de Havilland Aircraft. Like many other Western European air forces, the British Royal Air Force (RAF) was modernising its flying equipment following the onset of the Cold War. Among other things, it needed a new rustic, reliable and inexpensive initial training aircraft.

In December 1948, the Chipmunk won a competition organised by the RAF. De Havilland Aircraft signed the first of a series of contracts in February 1949. For the first time, a Canadian aircraft was to be built under license abroad. The RAF’s orders alone amounted to around 740 slightly modified aircraft – a remarkable total to say the least. The first British-made Chipmunk flew in August 1949.

Over the years, new and second hand Chipmunks made by de Havilland Aircraft also carried the colors of nearly 20 countries in Africa (Egypt, Ghana, Kenya and Zambia), America (Colombia and Uruguay), Asia (Burma (today’s Myanmar), Ceylon (today’s Sri Lanka), Iraq, Jordan, Kenya, Malaysia, Lebanon, Saudi Arabia, Syria and Thailand) and Europe (Denmark, Ireland and Portugal).

The single aircraft flown by the Fuerza Aérea Colombiana may have been acquired for evaluation purposes.

It should be noted that personnel from the Thai air force, or Kong Thap Akat Thai, drastically altered a dozen or so Chipmunks, renamed Chandras, around 1972-73.

De Havilland Aircraft made around 1 000 Chipmunk between 1949 and 1961.

For DHC, each of the aircraft exported by its parent company was equivalent to a lost contract. One and only one reason explained this state of affairs: the federal government’s monetary restriction policy. Indeed, the latter asked that potential customers of the Toronto aircraft manufacturer pay for their purchases in dollars, which was not always possible given their financial situation. These same customers were happy to pay in pounds, a situation which suited de Havilland Aircraft very well. In this regard, the case of Portugal was most interesting.

Like the RAF, the Portuguese air force, or Força Aérea Portuguesa, wanted to modernise its equipment. For example, it needed a new initial training aircraft. Unable to pay in dollars, the Portuguese government contacted de Havilland Aircraft and bought 10 Chipmunks. Better yet, it bought a license to produce the aircraft.

This transaction could be explained in various ways. For example, it helped maintain British influence in Portugal, a brutal dictatorship at the time, while at the same time boosting a tiny bit the war potential of NATO, a group which included the United Kingdom, Portugal and Canada.

A Portuguese state-owned firm, Oficinas Gerais de Material Aeronáutico, made around 65 Chipmunks between 1952 and 1961, for a grand total of around 1 285 aircraft made in Canada, the United Kingdom and Portugal between 1946 and 1961.

The Chipmunk was / is one of the most successful initial training aircraft of its time.

Many RCAF and RAF Chipmunk found takers when they were withdrawn from service. The Canadian aircraft proved to be very popular as an aerobatic aircraft. Many people referred to it as the Poor Man’s Spitfire – after the famous British Supermarine Spitfire fighter plane from the Second World War. And yes, the amazing collection of the Canada Aviation and Space Museum includes 3 (!) Spitfires.

As of early 2021, there were nearly 30 (airworthy?) Chipmunks in the Canadian civil aircraft register. There were about 105 and 115 (airworthy?) ones in those of the United States and United Kingdom, respectively.

To commemorate the withdrawal from service of the last Chipmunks of the RAF in 1996, a small British team undertook a world tour called Exercise Northern Venture. Two Chipmunk left the United Kingdom in July. Major forest fires in eastern Russia forced a return to the fold in August, however. The team took to the air again in May 1997. They arrived at Downsview at the end of June and received an enthusiastic reception. The 2 Chipmunks landed in the United Kingdom around mid-July after a journey of over 26 000 kilometres (over 16 000 miles).

Interestingly, an Indian state-owned firm, Hindustaan Eyarakraapht Limited / Hindustan Aircraft Limited, designed an initial training aircraft which closely resembled the Chipmunk. This HT-2, the first Indian powered aircraft, flew for the first time in August 1951. Hindustan Aircraft made more than 165 examples of this machine which served almost all in the Indian air force, or Bhāratīya Vāyu Senā, and the Ghana Air Force.

Before ending the present pontification, yours truly would like to mention some somewhat unusual versions of the Chipmunk.

In 1958, working in cooperation with an experienced British firm, Fison-Airwork Limited, de Havilland Aircraft designed an agricultural version of, you guessed it, the Chipmunk. Small, reliable, economical and agile, the Chipmunk was thought to have a great deal to offer to aerial application companies. It certainly was cheaper than a helicopter. The fact that the RAF had retired large numbers of Chipmunks in 1956 meant that aircraft could be acquired for conversion at a relatively low cost.

The new version included a newly designed cockpit canopy and a raised pilot seat. Thus modified, the rear cockpit enclosure offered as good a field of vision as the front seat of a standard Chipmunk. Modifications to the wings improved controllability and reduced the stalling speed, a useful feature for an agricultural airplane.

The agricultural Chipmunk could be used for either spraying or dusting. It could even be used to drop granulated fertiliser, a type of aerial application work known as top dressing. The glass-fiber hopper / tank was located in front of the pilot. Mounted almost directly above the aircraft’s centre of gravity, it filled the area previously occupied by the front seat, where the student pilot sat.

The Chipmunk’s low wing was said to offer very good visibility during the rather steep turns required when starting each new run. As well, it would ensure a better penetration of the pesticides, because the spray bars were so much closer to the ground. The aircraft’s wide swath, more than 25 metres (up to 90 feet), meant that spraying time and cost would be quite low as well. This, in turn, led de Havilland Aircraft to remark with some confidence that the Chipmunk was one of the most economical agricultural airplanes around. The hope, of course, was that it would duplicate the wide-scale success of its predecessor in the agricultural field, the aforementioned Tiger Moth.

De Havilland Aircraft bought an ex-RAF Chipmunk in March 1958. The conversion process began in May. The aircraft flew for the first time in early June. Within a few days, it was at Fison-Airwork’s main airfield. The aircraft’s career was short, however. It crashed in late July, while leased to Fison-Airwork. At the time, its experimental spraying equipment may still have been under evaluation. The pilot was seemingly uninjured.

This accident was quite embarrassing for de Havilland Aircraft because it had booked a flying slot at the 1958 edition of the annual airshow organised by the Society of British Aircraft Constructors, at Farnborough, England.

The company acquired a second ex-RAF Chipmunk in early August, converted it and had it flying by late August. This aircraft flew at Farnborough in early September.

Unfortunately, the time and effort expended by de Havilland Aircraft and Fison-Airwork did not lead to any order. The one and only agricultural Chipmunk left went into storage in June 1959.

A British aerial application company with a fleet of Tiger Moths, Farm Aviation Limited, bought the aircraft in October 1962, as well as the rights to convert more aircraft. Between 1963 and 1966, it bought two ex-RAF Chipmunks as well as some fuselages and a wrecked aircraft. Farm Aviation ended up with 4 agricultural Chipmunk which were flown for some time during the 1960s, using a new hopper that could be used to drop granulated fertiliser.

Farm Aviation did some design work on a new agricultural version of the Chipmunk to be powered by a more modern engine. As well, it offered plan sets for its agricultural Chipmunk to various aerial applicators and private pilots. Nothing came of either of these proposals.

Interestingly enough, a similar conversion was performed in Australia at pretty much the same time. This particular project was apparently the result of an announcement by the Australian Department of Civil Aviation that all Tiger Moths used for agricultural work in that country were to be taken out of service by 1966. It seems that soon after this, an agricultural pilot by the name of Michael “Mike” Sasin started to convert a Chipmunk for aerial spraying. Sometime later, he contacted a firm by the name of Aerostructures Proprietary Limited which agreed to complete the conversion. If successful, this modified aircraft could be the first of many, thus offering a possible replacement to the Tiger Moth.

Intrigued by the idea, Aerostructures got started on the project, using the parts of a pair of (British-made?) aircraft. Some difficulties were experienced. Indeed, it looks as if the Department of Civil Aviation was sufficiently dissatisfied with the prototype to convince Aerostructures to put it aside.

A second Chipmunk was then converted. Work on it was completed around June 1965. Variously known as the Aerostructures Spraymaster / Chipmunk Conversion, Sasin SA-29 Spraymaster or Sasin-Aerostructures SA 29 Spraymaster, it seemingly flew shortly thereafter and received its certificate of airworthiness in early September. Sasin test flew the aircraft that day. The following day, another pilot flew it again but ran out of fuel and crashed. His injuries were slight, but the aircraft was destroyed.

Aerostructures may have proposed an improved version of the Spraymaster. This aircraft did not proceed beyond the drawing stage.

A small outfit by the name of Bob Couper Proprietary Limited, located near one of Australia’s wheat growing areas, completed a second conversion, possibly also known as a Spraymaster, using the components of a pair of British-built Chipmunks. The resulting aircraft first flew in September 1965. Bob Couper used it as a sprayer until 1969. The Chipmunk was then flown as a glider tug for 3 years. A pilot by the name of John Turner acquired the aircraft at that point and flew it until 1976. The Chipmunk was then sold. At some point, it may, I repeat may, have been converted back into a standard Chipmunk.

Because of delays in completing a third agricultural conversion, presumably made using a British-built machine, Bob Couper decided to relinquish its option on the aircraft. As a result of this, the Chipmunk, also possibly also known as a Spraymaster, was delivered to a small operator called Tonair Proprietary Limited, in September 1966. It was severely damaged in a forced landing in December of that year. The Chipmunk was rebuilt and flew as a spraying aircraft in a wheat growing area between 1967 and 1969. That year, it was sold to a new owner for use as a glider tow. In 1970, it was damaged yet again. The Chipmunk was shipped to the United States in 1973. Its later career is unknown.

And so this issue of our blog / bulletin / thingee ends. I bid thee farewell, sweet reading friend.

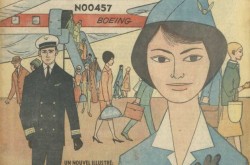

![One of the first de Havilland Canada Chipmunk imported to the United Kingdom. Anon., “De Havilland [Canada] DHC-1 ‘Chipmunk.’” Aviation Magazine, 1 January 1951, cover.](/sites/default/files/styles/large_1/public/2021-01/Aviation%20magazine%201er%20janvier%201951%20version%202.jpg.webp?itok=cy0f0mb_)

![A block of photographs showing some of the people involved in the bombing of beluga whales in the estuary and gulf of the St. Lawrence River. Anon., “La chasse aux marsouins [sic]. » Le Devoir, 15 August 1929, 6.](/sites/default/files/styles/thumbnail_7/public/2024-09/Le%20Devoir%2015%20aout%201929%20page%206.jpg?h=584f1d27&itok=TppdLItg)

![Peter Müller at the controls [sic] of the Pedroplan, Berlin, Germany, March 1931. Anon., “Cologne contre Marseille – Le mystère du ‘Pédroplan.’ [sic]” Les Ailes, 2 April 1931, 14.](/sites/default/files/styles/thumbnail_7/public/2021-04/Les%20Ailes%202%20avril%201931%20version%20big.jpg?h=eafd0ed4&itok=WnBZ5gMf)