A great Canadian success story you should know about: A brief look at the National Research Council of Canada flight impact simulators donated to the Canada Aviation and Space Museum, Part 1

Good day to you, my reading friend. If you have no objection, we will commemorate / celebrate the acquisition, in December 2012, ten years ago this month, of two very interesting devices by the wonderful Canada Aviation and Space Museum, in Ottawa, Ontario, more specifically two fascinating devices donated by a great Canadian institution, nay, a world famous Canadian institution.

Our topic of today is not as light hearted as some of our past fare, but I respectively make no apologies for that. To make a long and sad story short, while it is true that bird strikes are not a major cause of aircraft accidents and human fatalities, they are nonetheless a flight safety issue faced by airport operators, if not the airline industry as a whole.

Lest you be frightened away by that statement at the onset of this issue of our blog / bulletin / thingee, let me point out that an airliner is an extremely safe means of transportation, way safer than a motorcycle, bicycle or automobile.

The large majority of bird strikes occur near airports, during takeoff and early climb or final approach and landing. A Transport Canada industry guide pointed out several / many years ago that something like 3 out of 4 bird strikes whose altitude was known took place 150 metres (500 feet) or less above the ground. Aircraft taking off, flying with their nose up and heavily loaded with fuel, are especially vulnerable.

Flocks of birds are especially dangerous. The spring and fall migrations are dangerous times. Mind you, summer is also bad as young birds which have never seen an aircraft take to the sky. As might be expected, large and heavy migratory birds like the Canada goose are hugely dangerous. Add to that an increase in population for several / many large bird species (eagles, cranes, geese, pelicans, etc.), not to mention the fact that such birds are often quite comfortable living near humans, and you have the potential for serious accidents.

While bird strikes are rare events, all things considered, pilots need to be on lookout at all times. After all, back in October 1991, the crew of a jetliner reportedly hit an unidentified bird of great size at an altitude of almost 12 000 metres (more than 39 000 feet).

One should note that birds are not the only threat. Insects and, in some cases, bats can endanger aircraft. Indeed, land mammals can also be an issue. Hitting a deer on touchdown can have very serious consequences, especially if the aircraft is small.

Yes, yes, insects. I kid you not. The swarms of locusts that human populations have faced, and continue to face, can be mindbogglingly large. Some of them can cover an area of up to 130 square kilometres (50 square miles). The number of insects in such a plague is almost beyond comprehension: almost 13.5 billion very hungry individuals weighing around 38 000 metric tons (37 500 Imperial tons / 42 000 American tons).

People often wonder how something as small as a sparrow or starling can damage or bring down an aircraft. The answer to their question has to do with energy. The energy released by the impact of an 80-gramme starling hitting the nose of an airliner flying at 300 kilometres/hour is equivalent to that of a 720-gramme, 5.6-centimetre diameter steel ball hitting an automobile moving at 100 kilometres/hour.

If yours truly may be permitted to convert that statement into slightly different Imperial measurements, the energy released by the impact of a 3-ounce starling hitting the nose of an airliner flying at 180 miles/hour is equivalent to that of a 27-ounce, 2.25-inch diameter steel ball hitting an automobile moving at 60 miles/hour.

Now, just imagine that the 80-gramme starling is an 8-kilogramme Canada goose and repeat the calculations, using a well-known formula, E = 1/2 MV2, or energy equals mass times speed squared divided by 2.

Err, let me spare you the trouble, my reading friend. The weight and diameter of the steel balls hitting the automobile would be 72 kilogrammes and 26 centimetres. Using slightly modified Imperial measurements, a 3-ounce starling and an 18.75-pound Canada goose, the weight and diameter of the steel balls hitting the automobile would be almost 169 pounds and close to 10.5 inches. Pretty scary, is it not?

Worse still, soft objects like birds do not simply punch holes in aircraft the way a rock would. They tend to spread on impact, thus potentially causing more damage.

Given all of that, it becomes a lot easier to understand how the cost of bird strikes to airlines (repair costs, lost revenues, etc.) seemingly averaged $ 1 800 000 000 a year in the early 2000s. To these direct and indirect costs, one should add the ancillary costs faced by airport owners / operators, regulatory authorities, emergency response agencies, etc. Civil and / or criminal liability is something else that all players must keep in mind. All of these worries, and more, affected / affect / will affect an industry that is constantly struggling to stay out of the red.

And that despite the fact that the fuel burned during international flights is exempted from any and all taxes, a privilege that the airline’s industry trade organisation, the International Air Transport Association, is fighting tooth and nail to protect. You did not know about that little privilege, now did you? A potentially controversial comment if I may. How bad will things have to get, environmentally speaking (typing?), before something is done about said privilege? But back to the airline industry and its inclination toward the colour red.

You have doubts, my sceptical reading friend? Let me tell you a story and… Yes, a brief one, and… A very, very brief one. The May 1970 disintegration of a vital element during the development of the powerful and advanced Rolls-Royce RB211 turbofan engine was one of the many factors which seriously affected the service introduction of the new engine and significantly increased its development cost. The end result of all that was the bankruptcy (!) of Rolls-Royce Limited and the creation of a new government-owned firm, Rolls-Royce (1971) Limited. It is worth noting that the stupendous Canada Aviation and Space Museum has an RB211 in its collection.

Financial loss was / is not the worst of it, of course. As of 2019 or so and leaving military flying aside, bird strikes are known to have caused the death of more than 530 people. It is very likely that many other non fatal accidents, non fatal to humans that is, have gone unreported, especially if they occurred before the 1970s and / or if they involved general aviation type aircraft. One has to wonder if accidents also went unreported in Soviet bloc countries or mainland China.

The total number of bird strikes is, of course, much larger than the number of lethal accidents. Indeed, in most cases where large transport planes / airliners are involved, bird strikes cause limited amounts of damage. Airliner crews do not always realise they had hit something and ground crews do not always find bird remains. Even if there is some damage, the crews are routinely able to return to the airport they had just left or abort their take off before they run out of runway space.

Oddly enough, the reporting of bird strikes was not mandatory in most of the world for decades. In Canada, for example, that reporting became mandatory only in 2006. In the United States, it appears to be only “strongly recommended.” While large airlines tend to abide by the recommendations of the American authorities, small operators and private pilots are sometimes / often less compliant. Mind you, that tendency may also affect Canadian data gathering.

Over time, aircraft operators, aircraft makers and regulatory authorities came to realise that, as the number of aircraft flying increased, so would the number of accidents - and fatalities. Three approaches have been used to reduce the impact of bird strikes: moving birds away from the places where aircraft can be found, moving aircraft away from the birds and making aircraft as bird resistant as possible.

The first approach might be called bird management and control. Plants eaten by certain birds can be removed from the site of an airport. Trees and structures on which other birds like to roost can be removed as well. Scaring away the birds is another option. The methods used by airports vary a lot, from non lethal to lethal.

Yours truly remembers how, many, many years ago, a device producing sounds similar to those emitted by a seagull in distress was mounted on the site of the Rockcliffe Flying Club, a stone throw from the, words fail me, help me here, my reading friend, supercarlifragilisticexpialidocious Canada Aviation and Space Museum. Said device was put in place in the hope of reducing the number of seagulls near the airstrip of the flying club. Sadly, the resident avian population seemingly got used to the noise. Other devices were used later on and continue to be used to this day.

Yours truly is not all that fond of seagulls. And yes, my coat was hit by poop on one occasion, in the staff parking lot of the Canada Aviation and Space Museum. Mind you, years before, I had suffered a similar humiliation during a trip to London, England. The avian culprit that time was a pigeon emptying its bowel before going to sleep, under a bridge. Curse you all, rats with wings! Sorry, sorry.

Moving aircraft away from the birds is certainly feasible. Aircraft can stay clear of nature reserves, known migratory paths and other areas where birds congregate. As well, taking off and landing when birds are present in significant numbers should be avoided as much as possible. Slowing down at low altitude and spending as little time there as possible are good ideas. The catch with all that is that most pilots have little if any training in bird avoidance. Indeed, regulatory agencies around the globe seem to have no requirement for such training.

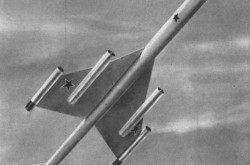

The last item on the list above, making aircraft as bird resistant as possible, is the one we will be looking at from now on. A great deal of time and money was, is and will be spent in making aircraft, primarily large transport planes / airliners, as well as their engines, as bird resistant as possible. The testing of aircraft components has been, is and will be of crucial importance. Special tools had to be designed from scratch.

Thus began the story of the flight impact simulators (bird carcass accelerating guns, bird impact simulators, bird projectile guns, compressed air launchers, FOD (foreign object damage) cannons, impact simulator guns, impact testing cannons, pneumatic launchers, etc.), in other words giant compressed air guns also known as bird guns, chicken cannons, chicken guns, linear chicken accelerators and rooster boosters.

The story of the bird proofing of aircraft apparently began during the Second World War with simulated bird impact tests on windshields. By early 1943, one such device – in all likelihood the ancestor of today’s flight impact simulators – was in use at Westinghouse Electric and Manufacturing Company, in the United States. It had been designed to test new airliner windshields developed to satisfy requirements developed by the Civil Aeronautics Administration. That flight impact simulator remained in service for some time after the end of the Second World War. It no longer exists. Pity. And yes, that flight impact simulator was at the heart of a July 2018 article of our blog / bulletin / thingee.

Some organisations in the United States and the United Kingdom developed flight impact simulators from the 1950s onward. By the mid 1950s (?), for example, de Havilland Engine Company, a subsidiary of a well known British aircraft making firm mentioned many times in our blog / bulletin / thingee since February 2018, de Havilland Aircraft Company Limited, seemingly had a flight impact simulator it used to test its jet engines. One has to wonder if that was not be the first time such a device was used in such a role. The chickens used for the tests came from a nearby farm. That device no longer exists.

Other British flight impact simulator went into service in later years. In May 1961, the Royal Aircraft Establishment commissioned one with a 152-millimetre (6 inches) bore and a 15.2-metre (50 feet) long barrel. It could fire birds weighing up to 1.8 kilogramme (4 pounds) at speeds of up to 1 100 kilometres/hour (680 miles/hour). In the fall of 1967, the National Gas Turbine Establishment completed a flight impact simulator with a 212-millimetre (8.35 inches) bore and a 21.3-metre (70 feet) long barrel. It looks as if neither of these devices still exists.

In the United States, the National Aviation Facilities Experimental Center of the Federal Aviation Agency (FAA) had a flight impact simulator in use by 1965 if not earlier. The Technical Development Center of the FAA, I think, on the other hand, had a 152-millimetre (6 inches) flight impact simulator with a 12.8-metre (40 feet) long barrel put in service no later than 1966. That particular device fired 1.8-kilogramme (4 pounds) birds. It looks as if neither of these flight impact simulators still exists.

The service introduction of these two flight impact simulators may not have been coincidental. Please note that what follows is very disturbing.

One of the catalysts in bird strike research was the crash of a Lockheed Electra airliner operated by an American air carrier, the deadliest of its type up to that day, in October 1960, in the harbour of Boston, Massachusetts. Shortly after take off, the airliner ran into a flock of starlings. Birds went into three of the four turboprop engines of the aircraft. An engine was shut down properly but two others suffered intermittent power losses. The crew eventually lost control. Only 10 of the 72 people on board survived, and 9 of these were seriously injured.

This tragedy came as a total shock to the airlines, airliner makers and regulatory authorities around the world. In Canada, it got people at the Department of Transport thinking. Around 1962, these people contacted the National Research Council of Canada (NRC), a world famous organisation mentioned many times in our blog / bulletin / thingee since May 2018, to see if something could be done to reduce the risk birds posed to aircraft.

In turn, NRC asked Malcolm Sheraton “Mike / Mac” Kuhring, a gentleman mentioned in July 2018 and October 2020 issues of that same blog / bulletin / thingee and the head of the Engine Laboratory of its Division of Mechanical Engineering, if he could form and chair a committee on that question. Thus was born, in 1962, the Associate Committee on Bird Hazards to Aircraft. Indeed, a crucial factor in the NRC’s request was the fact that the Engine Laboratory had been conducting research on the effects of foreign object ingestions on jet engines for some time.

It is worth noting that Canada in general and Kuhring in particular played a significant role in the early work done to reduce the risk birds posed to aircraft. Indeed, the associate committee was the first such committee on planet Earth.

By 1967, Canada was becoming the go to country in the study of bird strikes. Would you believe that 30 or so countries were sending detailed reports on such occurrences to the Department of Transport? Said reports were analysed and the resulting data sent to the International Civil Aviation Organization. That specialised agency of the United Nations Organization based in Montréal, Québec, then disseminated the data across the globe.

In 1969, the associate committee sponsored an international conference on bird strikes. Said conference, the first one ever, was held in early September, at Queen’s University at Kingston, located in… Kingston, Ontario. Experts from 20 or so countries took part in the proceedings.

In 1976, the associate committee helped publish a most interesting book by a wildlife biologist at the Canadian Wildlife Service (CWS), Hans Blokpoel. Entitled Bird Hazards to Aircraft, that landmark publication was done in co-operation with the CWS and Environment Canada. It was published simultaneously in Canada, the United Kingdom and the United States. A copy of that book can of course be found in the fantastic library of the Canada Aviation and Space Museum, the best aviation history library in Canada. (Hello, FSH!)

By 1976, no less than 30 or so countries in Africa, America, Asia, Europe and Oceania had bird strike committees.

Incidentally, in 1958, Kuhring had been put at the head of a sub-committee of NRC’s Associate Committee on a National Aviation Museum set up to examine the space made available for that museum in the new airport terminal building, at Uplands, near Ottawa. The following year, Kuhring was appointed Curator ad interim. That amateur aviation historian remained heavily involved in the project until the opening of the National Aviation Museum, today’s Canada Aviation and Space Museum, in October 1960, and this despite the fact that Kenneth Meredith “Ken” Molson had been formally appointed as curator in early July. To paraphrase Molson, it is hard to know how the creation of the museum could have taken place without Kuhring’s efforts.

Would you believe that a prestigious yearly award is named after Kuhring? Initiated by the Bird Strike Committee Europe, a group known in 2022 as the International Bird Strike Committee, the Mike Kuhring Prize recognises the highly significant contributions of individuals for improving flight safety in the field of bird strikes.

Creating a committee, however important that might be, did not have much of an impact on the real world. Testing of aircraft components was, is and will be of crucial importance. Special tools had to be designed from scratch. Thus began the story of the flight impact simulators (bird carcass accelerating guns, bird projectile guns, compressed air launchers, impact simulator guns, impact testing cannons, pneumatic launchers, etc.), in other words giant compressed air guns also known as bird guns, chicken cannons, chicken guns, linear chicken accelerators and rooster boosters, and…

What is it, my reading friend? I am repeating myself? Why, goodness me, I am. Sorry about that.

Today’s flight impact simulators are designed to fire real or synthetic birds at varying speeds. The component under fire, a windshield for example, is connected to instruments which measure its distortion and the force of the impact. In the case of an engine test, the instruments measure many parameters (temperature, pressure, distortion, etc.). In all cases, high-speed cameras record the flight of the projectile and its impact on the target. Some / many operators also use laser sensors. And yes, computers are used as well.

As far as yours truly is concerned, computers are no more than temperamental typewriters. I do not like computers and the feeling, I believe, is mutual. And I have the mental / psychological scars to prove that opinion.

It is worth noting that multiple barrel flight impact simulators have been and may be still used to test the resistance of large jet engines to multiple bird strikes, a situation known as flock ingestion.

Over the years, various operators of flight impact simulators have considered the possibility of using blocks of materials like gelatine, with or without some fibrous material, rather than fully feathered birds. Not everyone thought that was a good idea. True enough, synthetic birds offer certain advantages. Their use turned the clean up of the test area into a somewhat less unpleasant exercise, for example. The weight of synthetic birds could also be calculated very precisely, which eliminated the need to inject some water into a real bird or removed a small portion of its carcass to bring its weight as close as possible to the required figure for the test.

Aircraft and engine manufacturers have been using computer simulations for several years to complement and (largely?) replace flight impact simulators. That approach had / has a great deal to offer, especially during the research and development stages. Tests could be conducted anytime and anywhere, with a great deal of accuracy and consistency, for example. That virtual testing also allayed the concerns of various animal-welfare groups.

As of 2022, however, there were still quite a few flight impact simulators operating on this Earth. Some basic information on a few of these follows.

The Impact Physics Group of the University of Dayton Research Institute (UDRI), in Dayton, Ohio, has apparently no less than 12 (!) flight impact simulators. They vary in bore between 95 and 305 millimetre (3.5 to 12 inches). The length of their barrels, on the other hand, varies between 6.4 and 12.2 metres (21 to 40 feet), if not more. The most powerful of these devices can propel a projectile at speeds reaching 36 200 kilometres/hour (22 500 miles/hour)! The projectile in question is not the heaviest projectile fired by UDRI’s flight impact simulators, of course. Said projectile, after all, can weight up to 45 or so kilogrammes (100 pounds).

And no, the flight impact simulator able to fire such a projectile was not / is not used in conjunction with bird strike research, if only because the heaviest example of the heaviest flying bird, the great bustard, an avian omnivore found between Spain and China, tipped the scales at a measly 21 kilogrammes (46 pounds).

By comparison, a condor-like bird found in Argentina and extinct for more than 6 500 000 years weighed approximately 70 kilogrammes (approximately 155 pounds). I kid you not. Standing upright, Argentavis magnificens could have looked an 1.8 metre (6 feet) human right in the eye. That scavenger had a wingspan of up to 6.5 metres (21 feet 4 inches), but I digress.

Humm, as long as we are shooting the breeze here, did you know that some species of pterosaurs (Hello EP, EG and SB!), those warm-blooded flying reptiles which shared the Earth with dinosaurs, had wingspans of up to 11 metres (36 feet)? After a good meal, one of those critters might have tipped the scale at 250 kilogrammes (550 pounds)! By the way, those aerial giants, members of a family known as the Azhdarchidae, lived at the very end of the age of dinosaurs, about 66 million years ago.

And no, the Earth and its innumerable living beings were not created less than 10 000 years ago. Nay. Our big blue marble and the life it shelters it made their appearance about 4.5 and 3.7 billion years ago, give or take a few minutes. Dinosaurs and humans walking side by side? If I may be permitted to quote, out of context, a well known if fictitious English merchant of the 1840s, Ebenezer Scrooge, humbug!, but back to our story. Really.

From the looks of it, only one of the flight impact simulators in Dayton may, I repeat may, have been used in conjunction with bird strike research as of late 2022.

UDRI’s family of flight impact simulators entered service from 1975 onward, I think.

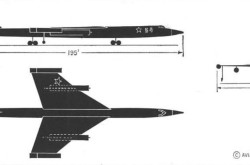

The United States Air Force’s Arnold Engineering Development Complex at Arnold Air Force Base, in Tennessee, on the other hand, has a 178-millimetre (7 inches) device with a 36.6-metre (120 feet) long barrel capable of firing birds / projectiles at speeds of up to 1 540 kilometres/hour (960 miles/hour) or 2 520 kilometres/hour (1 610 miles/hour), depending on the sources. Capable of firing items weighing between 1.6 and 25 kilogrammes (3.5 to 55 pounds), that flight impact simulator was originally built to test the canopies of military aircraft. It entered service in 1972.

Back in 2004, a barrel with a rectangular section was used to fire blocks of foam at the solid rocket boosters used to send into orbit the Orbiter Vehicles / Space Shuttles of the Space Transportation System. That very sad test program was instigated after the loss of the 7 crew members of the space shuttle Columbia, in February 2003.

Incidentally, the idea of firing non-cylindrical / spherical projectiles was apparently first mooted by an English writer, lawyer and inventor. In 1722, James Puckle apparently supervised the testing of his Defence Gun or Puckle Gun, a revolver-type firearm on a mount. The weapon fired 63 rounds in 7 minutes, in the midst of a driving rain storm, this at a time when an average soldier could fire 2 to 5 times a minute. For some reason, Puckle proposed that a cubic bullet version of his weapon be used against the Muslim soldiers of the Ottoman Empire. The idea went nowhere. Indeed, very few conventional Puckle Guns were made. That early rapid fire weapon was simply too clumsy, complex and undependable.

PPG Industries Incorporated, a diversified American corporation which supplied / supplies a variety of products, has a 254-millimetre (10 inches) flight impact simulator all but identical to the superb 10-inch gun developed in Canada, a device yours truly will look into at a later point. That firm arguably was / is one of the most important aircraft windshield makers in the world and was a long-time customer of the flight impact simulator team at Uplands. Indeed, Canadian personnel actually helped to develop that flight impact simulator commissioned in 1984. If truth be told, PPG Industries’ flight impact simulator was / is informally known as the Mark II 10-inch gun.

Boeing Company, an American firm which needs no introduction, a firm mentioned in several issues of our tremendous blog / bulletin / thingee since November 2017 if you must know, also has a 254-millimetre (10 inches) flight impact simulator all but identical to the 10-inch gun developed in Canada. That flight impact simulator was fabricated by PPG Industries for Dutch aircraft maker Naamloze Vennootschap Koninklijke Nederlandse Vliegtuigenfabriek Fokker but for some reason or other it ended up with the American aircraft maker instead. Unsurprisingly, that device was / is informally known as the Mark III 10-inch gun.

Interestingly enough, W.R. Davis Engineering Limited of Ottawa has produced flight impact simulators since 1995 or so. That production ranged from single barrel devices with a 178-millimetre (7 inches) or 254-millimetre (10 inches) bore, the so-called “Goose Cannon”, to multi-barrel devices with 203-millimetre (8 inches) bores. Initial velocities vary between 290 and 720 kilometres/hour (180 to 450 miles/hour). These flight impact simulators could / can fire a variety of projectiles, from fully-feathered birds to hailstones, either large individually launched ones or small ones launched in groups. The maximum weight of individual projectiles varied between 2 and 8 kilogramme (4.4 to 17.6 pounds).

One of these flight impact simulators can be found at the Faculty of Engineering of the University of New Brunswick, in Fredericton,… New Brunswick. Another is used by Pratt & Whitney Canada Incorporated of Longueuil, Québec, an aeroengine manufacturer known around the globe mentioned in several issues of our blog / bulletin / thingee since March 2018.

Now that we are back in Canada, let us look at other flight impact simulators currently in service in that country.

Two of these devices are in Uplands / Ottawa, where they are operated by NRC’s Aerospace Research Centre. The first of them was commissioned in 1998 as a 127-millimetre (5 inches) device with a 6.1-metre (?) (20 feet) long barrel. Put together by staff members of the Structures, Materials and Propulsion Laboratory of what was then the Institute for Aerospace Research, that device was designed to fit inside an engine test cell in order to perform ingestion tests with ice or fully feathered birds. Less than 10 actual test shots were realised with that flight impact simulator between 1999 and 2006.

The device was then modified a couple of times between 2007 and 2011. By the end of the process, it had a 5.1-metre (16 feet 9 inches) long barrel with an 89-millimetre (3.5 inches) bore.

A second flight impact simulator with an identical barrel was built by the same people, in 2011, and mounted beside its sibling. The twins, as they were / are sometimes / often called, if only informally, have been running ever since, more or less regularly.

The two devices have fired fully feathered birds weighing 3 ounces (85 grammes) at speeds of up to 660 kilometres/hour (410 miles/hour). They have also fired spheres of ice and aluminium of various sizes to simulate ice flying off aircraft as well as debris on runways that an airliner’s tires could pick up and hurl back at it.

As of 2022, one of the twins had a 152-millimetre (6 inches) bore. It was used to fire 1-kilogramme (2 pounds) birds.

The staff of NRC’s Aerospace Research Centre completed a most interesting flight impact simulator in 2019. This device had a 43-centimetre (17 inches) bore and was used for drone testing.

Would you like to know more about the flight impact simulators donated to the Canada Aviation and Space Museum in December 2022? Symphonic music to my ears! This being said (typed?), my reading friend, you will have to wait until next week. Sorry, sorry.

![A block of photographs showing some of the people involved in the bombing of beluga whales in the estuary and gulf of the St. Lawrence River. Anon., “La chasse aux marsouins [sic]. » Le Devoir, 15 August 1929, 6.](/sites/default/files/styles/thumbnail_7/public/2024-09/Le%20Devoir%2015%20aout%201929%20page%206.jpg?h=584f1d27&itok=TppdLItg)

![Peter Müller at the controls [sic] of the Pedroplan, Berlin, Germany, March 1931. Anon., “Cologne contre Marseille – Le mystère du ‘Pédroplan.’ [sic]” Les Ailes, 2 April 1931, 14.](/sites/default/files/styles/thumbnail_7/public/2021-04/Les%20Ailes%202%20avril%201931%20version%20big.jpg?h=eafd0ed4&itok=WnBZ5gMf)

![One of the first de Havilland Canada Chipmunk imported to the United Kingdom. Anon., “De Havilland [Canada] DHC-1 ‘Chipmunk.’” Aviation Magazine, 1 January 1951, cover.](/sites/default/files/styles/thumbnail_7/public/2021-01/Aviation%20magazine%201er%20janvier%201951%20version%202.jpg?h=2f876e0f&itok=DM4JHe5C)