I want to know what snarge is, I want you to show me, or not

Good day to you, my reading friend. Our topic today is not as humorous or light hearted as some of our usual fare, but I respectively make no apologies for that. To make a long and sad story short, while it is true that bird strikes are not a major cause of aircraft accidents and human fatalities, they are nonetheless among the most pressing flight safety issues faced by airport operators, if not the airline industry as a whole.

The large majority of bird strikes occur near airports, during takeoff and early climb or final approach and landing. Flocks of birds are especially dangerous. The spring and fall migrations are dangerous times as well. Mind you, summer is also bad as young birds that have never seen an aircraft take to the sky. As might be expected, large and heavy migratory birds like the Canada goose are hugely dangerous. Add to that an increase in population for several large bird species, like swans and geese, not to mention the fact that such birds are often quite comfortable living near humans, and you have the potential for serious accidents. The fact that air traffic is expected to increase significantly over the next decades will only make things worse.

People often wonder how something as small as a starling can damage or bring down a small aircraft. The answer to their question has to do with energy. The energy released by the impact of an 80-gramme starling hitting the nose of an airliner flying at 300 kilometres/hour is equivalent to that of a 720-gramme, 5.6-centimetre diameter steel ball hitting an automobile moving at 100 kilometres/hour. If yours truly may be permitted to convert this statement into slightly different Imperial measurements, the energy released by the impact of a 3-ounce starling hitting the nose of an airliner flying at 180 miles/hour is equivalent to that of a 27-ounce, 2.25-inch diameter steel ball hitting an automobile moving at 60 miles/hour.

Now, just imagine that the 80-gramme starling is an 8-kilogramme Canada goose and repeat the calculations, using a well-known formula (energy equals mass times speed squared divided by 2.) Err, let me spare you the trouble, my reading friend. The weight and diameter of the steel balls hitting the automobile would be 72 kilogrammes and 26 centimetres. Using slightly modified Imperial measurements, a 3-ounce starling and an 18.75-pound Canada goose, the weight and diameter of the steel balls hitting the automobile would be almost 169 pounds and close to 10.5 inches. Pretty scary, isn’t it?

Worse still, and I do apologise for the yuckiness, and for saying (typing?) last week that this week’s topic would not be smelly or yucky, soft objects like birds do not simply punch holes in aircraft the way a steel ball would. They tend to spread on impact, thus potentially causing more damage. Given all of this, it becomes a lot easier to understand how the cost of bird strikes to airlines seemingly exceeds 1 billion dollars U.S. a year. To these direct and indirect costs, one should add the ancillary costs faced by airport operators, regulatory authorities, emergency response agencies, etc. Financial loss is not the worst of it, of course. As of 2012, leaving military and private flying aside, bird strikes are known to have caused the death of 269 people.

The total number of strikes is, of course, much larger than the number of accidents lethal to humans. Indeed, in most cases where large airliners / transport planes are involved, bird strikes cause little or no damage. Light / private airplanes, not to mention the people on board, tend to suffer a lot more. How many collisions that involve no human injury have taken place over the past decades is unknown. Indeed, some wildlife management experts have suggested that 60 to 80 % of all bird strikes go unreported, for various reasons.

Airlines, airport operator, manufacturers and regulatory authorities have spent, are spending and will keep on spending a great deal of time and effort developing ways to reduce the impact of bird strikes,

- by moving birds away from the places where aircraft can be found;

- by moving aircraft away from the birds; and

- by making aircraft as bird resistant as possible.

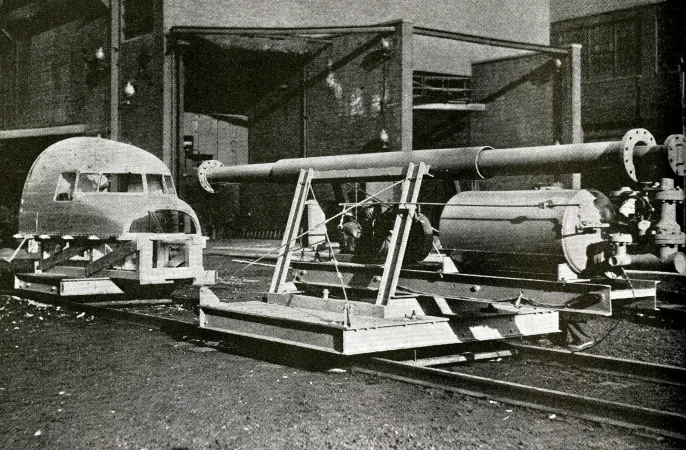

The photo at the start of this article can be linked to this third approach. A great deal of time and money has been, is and will be spent in making aircraft, primarily large airliners / transport planes, as well as their engines, as bird resistant as possible. Testing of aircraft components was, is and will be of crucial importance. Special tools had to be designed from scratch. Thus began the story of the flight impact simulators, also known as bird carcass accelerating guns, bird impact simulators, bird projectile guns, compressed air launchers, foreign object damage cannons, impact simulator guns, impact testing cannons, pneumatic launchers, etc. These giant compressed air guns are less officially known as bird guns, chicken cannons, chicken guns, linear chicken accelerators and rooster boosters.

The bird proofing of aircraft began during the Second World War, in the United States, with simulated bird impact tests on windshields. Work in this field was initiated around June 1942 by the Technical Development Division of the Civil Aeronautics Administration (CAA), the ancestor of today’s Federal Aviation Administration, an organisation with powers to regulate all aspects of civilian aviation in the United States. This being said (typed?), the engineers involved in the project were equally interested in solving a second issue, namely windshield icing.

By the end of 1942, the world’s first flight impact simulator was in use at the High Power Laboratory of Westinghouse Electric and Manufacturing Company, in East Pittsburgh, Pennsylvania. The engineering team of this subsidiary of Westinghouse Electric Corporation conducted hundreds of tests. Like you, perhaps, my reading friend, I could not see the relationship between bird strikes and an electrical laboratory. You see, the superfast valves at the heart of the simulator were originally developed for a new, gigantic compressed air circuit breaker. The high speed recording equipment used in the trials of the valves proved equally useful to record the results of the bird strike trials. It should be noted that the windshield testing work done in East Pittsburgh included the aforementioned research in de-icing.

Mounted on a small flatcar, the flight impact simulator could be fitted with two types of more than 6-metre (20 feet) long barrels, a 127 millimetre (5 inches) one and a 203 millimetre (8 inches) one. It was designed to fire humanely killed birds weighing up to 7.7 kilogrammes (17 pounds) at speeds of up to 435 kilometres/hour (270 miles/hour). This being said (typed?), smaller bird carcasses could reach speeds of almost 650 kilometres/hour (400 miles/hour). The birds used in the trials were primarily chickens and turkeys. Even then, the people at Westinghouse Electric and Manufacturing recognised the deadly threat posed by large birds like swans or geese.

Initial tests with windshields commonly used on American airliners showed that a 1.8 kilogram (4 pound) bird punched a hole through it at a speed of only 120 kilometres/hour (75 miles/hour). Later tests, on the other hand, showed that a glass / vinyl laminated windshield could resist the impact of a 6.8 kilogram (15 pounds) bird at close to 325 kilometres/ hour (200 miles/ hour), which was quite the improvement. This being said (typed?), the damage to the windshield was such that the pilot and co-pilot could no longer see through it.

The glass / vinyl laminated windshields used for the tests were supplied by well known American companies like Celanese Corporation of America, E.I. Du Pont de Nemours & Company, and Pittsburgh Plate Glass Company. This new technology was gradually adopted by aircraft makers and airlines.

The testing program conducted by Westinghouse Electric and Manufacturing came to an end in November 1943. This being said (typed?), the flight impact simulator did not remain idle for long. Testing resumed at the end of the winter of 1944-45 in a windshield testing facility recently completed at the Experimental Station of the CAA, in Indianapolis, Indiana. A 76 millimetre (3 inches) barrel was provided in addition to the 2 already in use on the flight impact simulator. It could launch birds weighing as less as 450 grammes (1 pound) at speeds of up to 725 kilometres/ hour (450 miles/ hour).

Testing continued into 1946. For the rest of that year and in 1947, the flight impact simulator team conducted tests for a number of well known American aircraft manufacturers: Beech Aircraft Corporation, Boeing Aircraft Company, Consolidated Vultee Aircraft Corporation, Curtiss-Wright Corporation, Douglas Aircraft Company Incorporated, Glenn L. Martin Company, Grumman Aircraft Engineering Company and Lockheed Aircraft Corporation. This pioneering device was retired at an undetermined date. Sadly enough, it no longer exists.

And yes, the magnificent, dare I say astonishing collection of the Canada Aviation and Space Museum, in Ottawa, Ontario, includes not 1 but 2 flight impact simulators, an 89 millimetre (3.5 inch) one and a 254 millimetre (10 inch) one, donated by the Institute for Aerospace Research of the National Research Council of Canada (NRC). And no, yours truly cannot promise that he will pontificate on these remarkable devices at some point in the future.

This being said (typed?), it is worth noting that NRC played a significant role in the early work done across the globe to reduce the risk birds posed to aircraft. Malcolm Sheraton “Mike / Mac” Kuhring, the head of the Engine Laboratory of NRC’s Division of Mechanical Engineering, formed the Associate Committee on Bird Hazards to Aircraft in 1962, for example. In 1969, this committee sponsored an international conference. In 1976, it helped publish a book by a biologist at the Canadian Wildlife Service (CWS), Hans Blokpoel. Entitled Bird Hazards to Aircraft, this book was done in co-operation with the CWS and Environment Canada. It was published simultaneously in Canada, the United Kingdom and the United States. The Canada Aviation and Space Museum is fortunate to count among its holdings a small collection donated by Blokpoel in 2005.

Interestingly enough, in 1958, Kuhring was put in charge of a sub-committee of the NRC’s Associate Committee on a National Aviation Museum set up to examine the space made available for this yet to be formed institution in the new terminal building at what was, in 2018, Ottawa Macdonald-Cartier International Airport. In 1959, Kuhring was appointed curator ad interim. This amateur aviation historian remained heavily involved in the project until the opening of the National Aviation Museum, today’s Canada Aviation and Space Museum, in October 1960, and this despite the fact that Kenneth Meredith “Ken” Molson had been formally appointed curator in early July. To paraphrase Molson, it is hard to know how the creation of the museum could have taken place without Kuhring’s efforts.

What’s this, my reading friend? You really want to know what snarge is? To paraphrase John Joseph “Jack” Nicholson in the very successful 1992 movie A Few Good Men, can you handle the truth? Very well, you have been warned. Snarge is the technical term describing what is left of a bird after it collides with an aircraft. And that’s it for this week.

![A block of photographs showing some of the people involved in the bombing of beluga whales in the estuary and gulf of the St. Lawrence River. Anon., “La chasse aux marsouins [sic]. » Le Devoir, 15 August 1929, 6.](/sites/default/files/styles/thumbnail_7/public/2024-09/Le%20Devoir%2015%20aout%201929%20page%206.jpg?h=584f1d27&itok=TppdLItg)

![Peter Müller at the controls [sic] of the Pedroplan, Berlin, Germany, March 1931. Anon., “Cologne contre Marseille – Le mystère du ‘Pédroplan.’ [sic]” Les Ailes, 2 April 1931, 14.](/sites/default/files/styles/thumbnail_7/public/2021-04/Les%20Ailes%202%20avril%201931%20version%20big.jpg?h=eafd0ed4&itok=WnBZ5gMf)

![One of the first de Havilland Canada Chipmunk imported to the United Kingdom. Anon., “De Havilland [Canada] DHC-1 ‘Chipmunk.’” Aviation Magazine, 1 January 1951, cover.](/sites/default/files/styles/thumbnail_7/public/2021-01/Aviation%20magazine%201er%20janvier%201951%20version%202.jpg?h=2f876e0f&itok=DM4JHe5C)