A somewhat forgotten aspect of the history of No. 425 Squadron (Alouette), Part 3

Good day for the third time, my reading friend, and welcome to the last part of this special edition of our blog / bulletin / thingee. With your permission, your humble servant would like to dedicate these many lines to the story of Victory Aircraft Limited, a Canadian aircraft manufacturer gone for ages and, in particular, to the production program of the British Avro Lancaster four engine heavy bomber.

As you and I know, the beginning of the Second World War in September 1939 was preceded by a series of increasingly serious crises. Although away from areas of tension, the federal / Canadian government realised very well that the risk of war was increasing. In 1936, Prime Minister William Lyon Mackenzie “Rex” King created a Cabinet Defence Committee that would coordinate and define the policies of his government. All the big guns in the cabinet were in it, namely King, Charles Avery Dunning, Minister of Finance, and Ernest Lapointe, Minister of Justice and King’s right hand man in Québec. Ian Alistair Mackenzie, Minister of National Defence, was also part of this group, even though he was not one of the big guns in cabinet.

At the first meeting, members of the committee heard reports prepared by the Canadian armed forces. The news was bad and the deficiencies, numerous. King and his ministers therefore decided to launch a rearmament program. The financial resources of the country being too limited, the federal government could not afford to buy all the equipment recommended by the Department of National Defence. King then began to take an increasing interest in the potential importance of the Royal Canadian Air Force (RCAF) for the defence of the country.

Without being decisive, a meeting with British Prime Minister Stanley Baldwin in October 1936 played a significant role in what followed. The latter suggested that King think especially of military aviation. Even if Canada was one of the least vulnerable countries, an air force would be most useful in case of attack. Baldwin did not seem to believe that a navy or army was worth the money.

To these military arguments was added the fact that unlike the Canadian Army and the Royal Canadian Navy (RCN), the RCAF did not awaken bad memories, such as the anti-conscription riots of the Easter weekend of 1918 and the difficulties surrounding the creation of the RCN in 1910. In the latter case, the official opposition seemed rather to favor the donation of a large sum of money to the United Kingdom so that it could strengthen the Royal Navy.

In any event, even before the end of 1936, King decided that the RCAF would be Canada’s first line of defence. In the event of danger, its units could indeed concentrate very quickly and ensure the territory’s protection in collaboration with the RCN and the Canadian Army. As far as King was concerned, this policy also put an end to the idea of a Canadian Army expeditionary force, closely linked to the idea of conscription and the potential danger that this question posed to the unity of the country.

In September 1936, the Joint Staff Committee of the Canadian armed forces completed a five-year rearmament program. Of the expected 200 million dollars, close to 75 would go to the RCAF. The committee established its requirements for 23 squadrons divided into two groups: 11 permanent squadrons equipped with combat aircraft and 12 non-permanent squadrons equipped with advanced training aircraft.

While King accepted the need for a rearmament program, if only to take into account Canada’s responsibilities on the international scene, he was horrified by the potential cost of this program and sought to reduce its magnitude. He achieved his goal, at least until September 1939. The beginning of the Second World War and, even more, the fall of France, in June 1940, put everything in question.

It goes without saying that the success of the RCAF’s rearmament program depended largely on the situation of the local aircraft industry. In September 1936, the Joint Staff Committee prepared a lucid comment on that subject. To fulfill its mission, an air force had to rely on well-equipped factories that produced aircraft and engines. Anyone who relied on this criterion was forced to conclude that Canada did not have an aircraft industry worthy of the name. In fact, with respect to aircraft, Canadian manufacturers did little more than assemble parts imported from abroad or repair aircraft already in service. Worse still, there was no engine manufacturing plant in Canada. Given the situation, fast deliveries were not to be expected.

Industry spokespersons enthusiastically acknowledge the importance accorded to the RCAF in the new Canadian defence policy. As the year 1936 ended, stagnation and discouragement disappeared like snow in the sun. As the RCAF had no combat aircraft that were even somewhat modern, the Department of National Defence signed the first of several contracts in that regard with Canadian aircraft manufacturers. From one end of the country to the other, they were feverish preparations to produce the combat and training aircraft ordered. The most lucid among the defenders of the Canadian aircraft industry hoped that the federal government would not try to do too much. Indeed, the thinness of defence budgets, not to mention the indifference of previous years, would not be erased in a few months.

The first Westland Lysander Army cooperation aircraft manufactured by National Steel Car Corporation, Malton, Ontario, August 1939, MAEC, KMM-0652.

The last combat aircraft production project of the RCAF rearmament program signed prior to the start of the Second World War touched upon observation and cooperation with the Canadian Army. In late 1937 or early 1938, as it did for all other combat aircraft ordered to date, the Department of National Defence asked the Royal Air Force (RAF) to suggest a machine suitable for the needs of the RCAF. The latter proposed the Westland Lysander, a new single engine two seat aircraft. The Department of National Defence approached National Steel Car Corporation Limited of Hamilton, Ontario, to discuss the possibility of an order.

Founded in 1920, this major railroad equipment manufacturer then had Robert James Magor as President and Chief Executive Officer. This businessman wanted to keep the Canadian manufacturing industry at the cutting edge of technology. Conscious since at least 1936 that aeronautics was a sector with a future and preoccupied by the aggressiveness of National Socialist Germany, Magor launched the construction of an aircraft factory at Malton, near Toronto. He apparently wanted to gain a good experience in aeronautics by licensing foreign aircraft before launching original aircraft designs.

In such a context, the discussions surrounding the possibility of a Lysander order were obviously welcome. National Steel Car signed a contract with the Department of National Defence and quickly acquired the Lysander’s production rights. National Steel Car actually won two orders totaling 28 Lysanders in March and May 1938. The brand new factory that would manufacture them opened before the end of summer. The first Canadian Lysander flew in August 1939. However, deliveries did not proceed as quickly as expected. In fact, the Department of National Defence had forgotten to order the propellers, manufactured in the United Kingdom.

The prototype of the twin engine three seat fighter Bréguet Br 690 C3, the first member of the family of multi-mission aircraft of the limited company of aviation workshops Louis Bréguet. L'Aéronautique, December 1938, 3.

National Steel Car was then involved in another production project, proposed by the Société anonyme des ateliers d’aviation Louis Bréguet, which began in February 1939, in Paris. A French businessman went to Canada soon after. He proposed to businessmen to create a central society run jointly by a French organisation and two Canadian companies. Capital being scarce and investors, cautious, one Canadian participant withdrew. National Steel Car continued alone. Despite these difficulties, the French Air Ministry maintained its offer: an initial contract for 144 twin engine two seat assault aircraft, possibly Bréguet Br 695 AB2s equipped with American engines, and the possibility of additional orders.

Informed by his French counterpart, Guy La Chambre, the British Secretary of State for Air, Sir Howard Kingsley Wood, suggested that he reconsider this new factory project near Toronto. Given that its entry into service could not take place for at least a year, it would be better to optimise the use of existing Canadian aircraft manufacturers. Such cooperation would also diminish the competition for equipment and qualified personnel, two rare commodities in Canada. La Chambre was willing to study this proposal, without abandoning the plan for the factory.

By the end of the summer of 1939, the negotiations seemed already quite advanced. National Steel Car owned the rights to manufacture the Br 695 and was planning an expansion program. In September, the French Air Ministry set the terms of a production contract. In fact, it was dealing with a company, Overseas Aircraft Limited, which had its roots in a recent alliance between National Steel Car and the powerful French bank Lazard Frères et Compagnie. This new company and its factory then existed only as projects.

Be that as it may, the British Air Ministry felt stuck between its desire not to get in the way of France and its fear of being criticised if it let its great ally monopolize part of the Canadian aircraft industry. Some senior officials blamed National Steel Car and Magor, an ambitious man it was said. They proposed that pressure be exerted so that National Steel Car abandoned its French project. In October 1939, the British Air Ministry obtained from its French counterpart an assurance that the signing of a production contract would be delayed. One of his representatives also visited Magor to tell him that producing the Br 695 could harm possible British Lysander orders. More interested by these and aware of the veiled threat of the British, National Steel Car withdrew from the Br 695 project.

If it was true that, during the summer of 1939, the Royal Air Force (RAF) and the Indian Air Force, then under British control, thought about ordering 300 Lysanders in Canada, the fact was that the enthusiasm of the British Air Ministry soon decreased. The United Kingdom’s parts and engine plants were already working at full capacity, which meant that a major Canadian contract would only complicate things. Let us remember that there was no engine production plant in Canada at this time. Therefore, one had to choose between producing Lysanders in Canada or in the United Kingdom. Any decision concerning an overseas order would have to be of a political nature.

Realizing that the British Air Ministry could order just a few aircraft, National Steel Car tried to revive the Br 695 production project. If this organisation no longer saw this as a problem, its French counterpart was no longer interested. Even worse, the British Air Ministry ordered only 50 Lysanders in February 1940. National Steel Car protested. Not wanting to open its flank to critics, the United Kingdom ordered 100 more aircraft. In March 1940, the Department of National Defence ordered an additional 92 Lysanders for the RCAF. National Steel Car thus planned to manufacture 270 Lysanders.

The German attack of May 1940 dealt a serious blow to the reputation of the Lysander. The squadrons of the RAF were decimated. National Steel Car was concerned that British orders would be canceled. Even worse, the Department of National Defence reduced its second order to only 9 Lysanders. In Malton, there was anger. National Steel Car’s backlog went from 270 to 187 aircraft, down 30 percent. The department had to make adjustments. Its second order went from 9 to 47 Lysanders, for a grand total of 75 aircraft. After intense negotiations, Canada and the United Kingdom also came to an agreement. The 150 British Lysanders were delivered to the RCAF, which used them within the scope of the British Commonwealth Air Training Plan, which had schools across Canada. The last Canadian Lysander went into service in October 1942.

The involvement of the British government in the evolution of the Canadian aircraft industry went beyond the case of the Lysander and the other British combat aircraft ordered by the RCAF. The tensions that appeared in Europe during the second half of the 1930s, mentioned above, aroused particularly strong reactions in the United Kingdom. In the view of many, the rearmament program of the RAF was not moving fast enough. To put an end to these criticisms, the government of Arthur Neville Chamberlain multiplied the contracts. It even thought of ordering aircraft in North America, especially in the United States, but also in Canada – an assumption that the British aircraft industry was very unhappy about.

Thus being said, the benefits of greater collaboration outweighed the disadvantages. British factories were vulnerable, but Canada was beyond the reach of German air force bombers. The creation of a production potential in Canada could thus have a deterrent effect. It could also encourage American aircraft manufacturers to produce in Canada, protected from the neutrality laws that would prevent any delivery of American war material to the United Kingdom in the event of a conflict. Better yet, it could lead to greater integration of Canada into the defence of the United Kingdom and the Commonwealth.

In June 1938, the British government sent a mission whose objective was to sign an aircraft production contract. The King government, which remained on the sidelines, nevertheless demanded that the British not interfere in any way with the RCAF’s rearmament program. If the King government hoped that the national aircraft industry would develop thanks to its sole resources, he nevertheless hoped that British contracts would allow it to settle on a more solid basis – a paradoxical position that it recognised more or less openly.

One of the Handley Page Hampden medium bombers manufactured by Canadian Associated Aircraft Limited. MAEC, KMM-05354.

The British mission and the Canadian industrialists began their discussions around August 1938. Developing a draft contract was not easy. Indeed, the two largest firms, National Steel Car and Canadian Car & Foundry Company Limited (CCF), the largest railway equipment manufacturer in the country, wanted to dominate both the project and the country’s aircraft industry. Anxious to avoid trouble, the British mission left to the Canadian industrialists the calculation of the number of aircraft to order. That number, eighty British Handley Page Hampden twin engine bombers, ultimately matched the British Air Ministry forecast. This order being too small to occupy all aircraft manufacturers, some companies were sacrificed. The six companies involved in the group, called Canadian Associated Aircraft Limited, were, for Québec, CCF, Canadian Vickers Limited and Fairchild Aircraft Limited, and for Ontario, Fleet Aircraft Limited, National Steel Car and Ottawa Car Manufacturing Company.

The presence of Ottawa Car Manufacturing, a firm of secondary importance that manufactured tramways and buses, must be highlighted. This subsidiary of Ottawa Electric Railway Company, itself a subsidiary of Ahearn & Soper Limited, belonged to the Ahearn family, which favoured the ruling party in Ottawa.

The British mission and the Canadian industrialists signed a contract in November 1938. Given that the British government did not inject more money into the program, it was its counterpart in Canada that defrayed the costs of constructing the factories in Malton and Saint-Hubert, where took place the assembly of the Hampdens, the elements of which were manufactured in the factories of the six members of Canadian Associated Aircraft.

As the year 1939 began, Canadian aircraft manufacturers were still waiting for plans and specifications from the British aircraft. Out of patience, Fleet Aircraft President William John “Jack” Sanderson travelled to London. His visit to the Air Ministry went nowhere. The Canadian High Commissioner in London then threw himself into this battle without paying too much attention to the instructions of non-interference from Ottawa. With the support of Charles Vincent Massey, Sanderson got the plans and specifications of the Hampden. Canadian Associated Aircraft was nonetheless not out of the woods yet. The adaptation of a British production system to the realities of the North American continent did not go smoothly.

These problems were so serious that some people in the United Kingdom questioned the signing of a second production contract for a version of the Short Stirling four engine heavy bomber fitted with American engines. A contract to this effect was signed in January 1940. The Canadian aircraft manufacturers were just recovering from these difficulties that another, more serious crisis fell upon them. In May 1940, the German armed forces on the offensive. The United Kingdom, soon alone to face Germany, put a stop to the delivery of Hampden parts and equipment for several weeks. With delays adding up, the companies involved in Canadian Associated Aircraft quarrelled more and more openly. Devoid of a central administration worthy of the name, the group was an artificial creation that united some long-time rivals not too successfully.

Before I forget, I would like to move away from our subject for a few moments. Austro-Hungarian-born British film producer Alexander Korda, born Sándor László Kellner, called on famous British writer Herbert George Wells, a giant of world science fiction literature, to write a screenplay for a science fiction film that owed a lot to aviation. Impressive but pretentious, Things to Come of 1936 was inspired by a novel, The Shape of Things to Come, published in 1933. The bombing of a large unidentified city, but most likely London, prefigured that of the small town of Gernika / Guernica, in April 1937, during the Spanish Civil War.

Shaken by the terrible conflict that ensued, the whole world soon returned to barbarism. Wells imagined its saviours in the form of an international elite which based its power on mastery of the sky. This authoritarian, not to say fascistic, approach fascinated more than one author of the period between the two world wars.

The crucial point of this digression was / is that the future pilot hero of Things to Come was played by Canadian Raymond Hart Massey, grandson of the founder of the Canadian firm Massey-Harris Company Limited, the largest manufacturer of agricultural machinery in the Commonwealth, and brother of the High Commissioner of Canada in London. Ours is a small world, is not it?

The first Canadian Hampden flew in August 1940. With the Stirling production project being delayed, Canadian Associated Aircraft received an order for eighty more Hampdens. Roughed up for months by the orders and counter-orders of the British Ministry of Aircraft Production, the Department of Munitions and Supplies, responsible for the production of war material in Canada since April 1940, was against the production of the Stirling. The entire aircraft industry would suffer the consequences of such a project, it believed. The goodwill of the King government, however, outweighed these practical considerations. The Stirling production program was not abandoned.

Before getting fully on board, however, Minister of Munitions and Supplies Clarence Decatur “C.D.” Howe asked that a team of production technicians be loaned to him. United Kingdom aircraft manufacturers needing all their experts, the Ministry of Aircraft Production refused. The Stirling production project, one hundred and forty aircraft in all, was therefore abandoned in December 1940. A project to build British Handley Page Halifax four engine heavy bombers, launched in December 1940, was dropped in early 1941. Worse still, the British Ministry of Aircraft Production no longer placed much importance on the Canadian Hampdens and the elements coming from the United Kingdom often arrived late. The last aircraft did not leave the assembly line until spring 1942. The Hampden had been obsolete for quite some time. Canadian Associated Aircraft apparently ceased to exist shortly thereafter.

The Department of Munitions and Supplies began thinking as early as the summer of 1940 about the aircraft that would succeed the Lysander at the National Steel Car plant. In October, it thought about ordering 200 American-designed twin engine medium bombers, Martin B-26 Marauders perhaps, for the RCAF. The British Ministry of Aircraft Production did not seem interested. It proposed that the Malton plant produce an American four engine heavy bomber for the RAF. The federal government did not seem interested. Canada, according to it, was already doing enough for the United Kingdom.

A Martin B-26 Marauder of the United States Army Air Forces. United States Air Force, via Wikipedia.

In April 1941, the Department of Munitions and Supply ordered an indeterminate number of Marauders – at least 200 it was said. This order, which would finally end the chronic underutilisation of National Steel Car’s facilities, announced a realignment of Canadian defense procurement policies for the defence of Canada. American aircraft would gradually replace British equipment. The British themselves did not seem to oppose this, on the contrary. The production program of the Marauder was quickly questioned, however. The reliability of the first production examples of this powerful aircraft left something to be desired, for example. Worse still, the British tried to obtain the first thousand Marauders produced in Canada. Faced with these problems, the Department of Munitions and Supply abandoned the Marauder project in November 1941. There was now an urgent need to find a production program for the Malton plant.

For some time then, the British Ministry of Aircraft Production had been trying unsuccessfully to obtain the support of its American counterpart for a project to produce a British four engine heavy bomber in the United States. It then turned to the Department of Munitions and Supply The proposed aircraft, the brand new Avro Lancaster, would be manufactured by CCF. The department agreed to cooperate but imposed its conditions. National Steel Car had to join the project, for example, and CCF would receive all the engines needed to manufacture a number of Hawker Hurricane fighter aircraft destined to the RCAF and no longer the RAF. Despite these discussions, the future of a four engine heavy bomber production project remained uncertain.

The conditions imposed by the Department of Munitions and Supply were due to the fact that, to a certain extent, Canada had disarmed itself for the benefit of the United Kingdom and Commonwealth by delivering to the RAF virtually all combat aircraft produced domestically. By the end of 1940, Howe and Charles Gavan “Chubby” Power, the Minister of National Defense for Air, proposed that the Department of Munitions and Supply order Hurricanes for the RCAF. The British Ministry of Aircraft Production initially refused but eventually said yes. Informed of the project, the staff of the RCAF refused these aircraft which it considered obsolete. The Cabinet War Committee, surprised and perhaps a little annoyed, brushed aside this opinion and signed a contract with CCF in July 1941 for eighty Hurricanes. The RCAF received its first aircraft in December 1941. The equipment needs of the RCAF were so dire that the RAF transferred to it 72 of the Curtiss Kittyhawk fighter aircraft it was receiving from the United States. These aircraft entered service from October onward.

The Japanese attack of 7 December 1941 against the United States Navy base of Pearl Harbor, in the Hawaiian Islands, and the entry into the war of the United States changed everything. Many people feared Japanese attacks on strategic targets in British Columbia. Anxious to defend the national territory, Power decided in early 1942 to requisition 400 Hurricanes destined for the RAF. The British government refused. The Rolls-Royce Merlin engines of these aircraft, built under license in the United States, were a rare commodity indeed that the RAF and the United States Army Air Forces competed for. The federal government, surprised and irritated, issued an ultimatum. If the opposition of its British counterpart continued, it would sell the Hurricanes to the American government so that the latter could transfer them to Allied air forces. The British took the hit.

In Ottawa, some Cabinet members were concerned, but Howe remained confident. In March 1942, the Director General of Aircraft Production at the Department of Munitions and Supply, Ralph Pickard Bell, proposed to slow down the production of the Lancaster and another bomber with Merlin engines, the de Havilland Mosquito, to take possession of the engines delivered in excess. Surprised by the vehemence of the Canadian reaction regarding the 400 Hurricanes, the British protested and then bowed down. Deliveries to Canadian fighter squadrons and operational training units began in June.

The RCAF appeared to have used only 250 of these Hurricanes. The others may not have been assembled. They may, however, have served with the Indian Air Force and / or the air forces of the Soviet army, but back to our story.

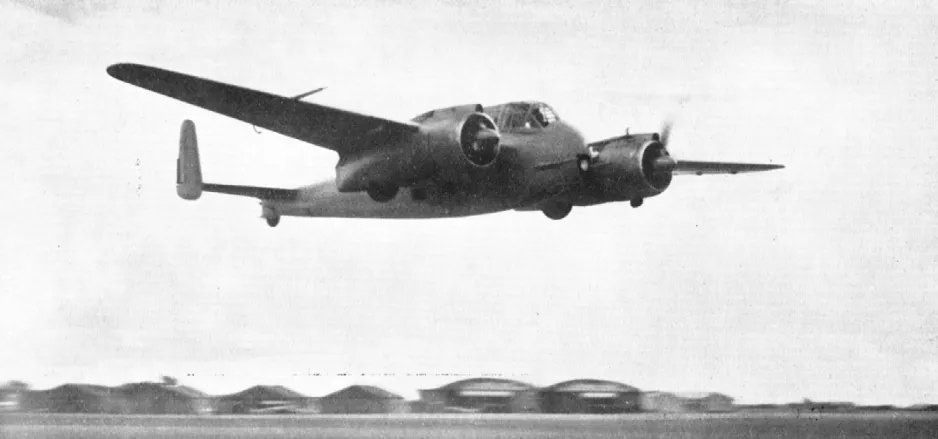

An Avro Lancaster heavy bomber of No. 619 Squadron, RAF, circa 1944. Royal Air Force, via Wikipedia.

National Steel Car got a contract for 300 Lancasters in December 1941. Another identical order followed soon after. CCF withdrew from the production program in January 1942, however. The factories of both companies were too far from each other. In addition, CCF liked to do its own thing. British and Canadian authorities were willing to accept this withdrawal, which facilitated the new production program. Anxious to maximise interchangeability with British-made Lancasters, National Steel Car ordered costly and modern production equipment. True to its habits, it financed most of these purchases from its own resources – an approach that was virtually unique in the Canadian aircraft industry of the time.

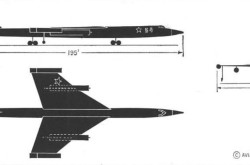

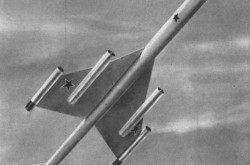

It would be useful and, at least I hope so, interesting to digress a few moments on the Lancaster. In 1936, the RAF launched a competition to modernise the equipment of its medium / heavy bombing squadrons. A few months later, it ordered two prototypes of a powerful twin engine aircraft of advanced design. Tested in July 1939, the Avro Manchester entered service in November 1940. The poor reliability of its engines led to its abandonment, however. A modified version equipped with four engines took to the sky in January 1941. Renamed Lancaster, the new heavy bomber stirred enthusiasm. It went into service even before the end of the year. With close to 7 400 examples manufactured in the United Kingdom and Canada, the Lancaster played a crucial role in the RAF’s bombing campaign against Germany. This robust and reliable bomber was / is one of the most famous combat aircraft of the Second World War, if not the 20th century. Let us now re-seize the thread of our story.

The production of a complex and large aircraft like the Lancaster proved difficult. In some cases, the problems stemmed from the National Steel Car head office in Hamilton. In the spring of 1942, hoping to improve things, the Department of Munitions and Supplies imposed the appointment of David Boyd as General Manager of the Malton plant. Boyd’s reputation was second to none; he had organised the production of the Hurricane for example. The President and Chief Executive Officer of National Steel Car accepted this change. The premature death of Magor put everything in question. From then on, National Steel Car’s Board of Directors increasingly interfered with the Lancaster production program.

Out of patience, Boyd contacted Howe. He denounced the incompetence of the Board of Directors and recommended the expropriation of the Malton plant as the only way to save the Lancaster production program. The members of the board were furious. They further accentuated their pressure. Boyd resigned in October 1942. Many engineers and employees protested vehemently. Recognizing the problems that had plagued the Malton plant for more than two years (multiple delays, rotten labor relations, poor performance and extravagant board of directors), Howe ordered the board to rehire Boyd. It refused. Usually opposed to state intervention in private industry, the Minister of Munitions and Supplies nationalised the Malton plant which became Victory Aircraft Limited at the first stroke of midnight on 5 November 1942. The federal government handed over four million dollars to National Steel Car in February 1943, as compensation.

Did you know that, when the expropriation process got under way, Victory Aircraft was to be called Allied Aircraft Limited? A last minute search showed that a firm by the name of Allied Aircraft Corporation had been formed in 1917, in the United States. If I may add my own grain of salt here, a firm by the same name was formed around 1939, also in the United States. And it was that Victory Aircraft became Victory Aircraft.

This expropriation of the National Steel Car factory, a Canadian first, certainly caused some stir. This being said, it dramatically improved the situation at the plant. The first Canadian Lancaster flew in August 1943. In an effort to increase Lancaster production in Canada, the British government lobbied its Canadian counterpart so that the new and ultramodern Cartierville factory of the shipyard and aircraft manufacturer Canadian Vickers received an order. This maneuver went nowhere.

As Minister of Munitions and Supplies, Howe readily acknowledged the importance of social peace in Canada. Union militancy did not always please him, but he managed to be conciliatory in most cases. For example, Victory Aircraft employees had many tax benefits and services: food services, medical expenses, subsidised housing and transportation, pay-for-performance program for hourly paid employees, and reduction of the work week, from 55.5 to 48 hours. These measures were a credit to the Department of Munitions and Supplies.

Howe and his department also acted in another area. They wanted to add a union representative to the boards of directors of the crown corporations they had created. In most cases, these boards bowed to their will. The board of Victory Aircraft resisted. This was a matter of principle, said President and Chief Executive Officer John Paris “Jack” Bickell, who had not been consulted. Howe told him that the presence of a union representative was not negotiable. The businessman and former president of Maple Leaf Gardens in Toronto resigned in January 1944 with his entire Board of Directors. This team was quickly replaced by another, more cooperative one.

Victory Aircraft ultimately produced 422 Lancaster bombers and 8 Lancaster airliners between 1943 and 1945. Seventy aircraft were canceled in May 1945, at the end of the fighting in Europe. A further 100 Lancasters were to be manufactured in another form – an upgraded version of the aircraft known as the Lincoln. This order was cancelled in August 1945, at the end of the fighting in the Pacific. The only Lincoln, completed to keep busy the few employees of the firm who have not been fired, flew in October.

The excellent quality of the Canadian Lancaster bombers, the most complex aircraft manufactured to date in Canada, compensated only to a certain extent for the fact that many of them entered service too late, in 1945, when the Second World War was almost won.

Interestingly, the Lancaster airliners originate from a project of the federal government which wanted a non-commercial air service for government officials and mail that its British counterpart could not, or did not want to, transport. Legal and diplomatic considerations led to the creation by the national carrier, Trans-Canada Air Lines, now Air Canada, of a separate entity, the Canadian Government Trans-Atlantic Air Service, in April 1943. The American and British governments having refused to provide him with aircraft, Howe obtained permission from the British Ministry of Aircraft Production to convert some Lancasters manufactured in Canada into airliners. A British Lancaster modified in the United Kingdom made the first flight of the new service in July. Victory Aircraft modified eight additional aircraft in 1943-45. The first of them flew in September 1943.

This writer wishes to note that the Lancaster airliners used by the Canadian Government Trans-Atlantic Air Service were similar but not identical to the Lancastrian of the British aircraft manufacturer A.V. Roe & Company (Avro). In fact, this airliner and military transport aircraft originated from the aircraft converted by Victory Aircraft. The first Lancastrian flew around February 1945.

Realising the importance of air transport during and after the war, Howe wanted to replace the Lancasters of the Canadian Government Trans-Atlantic Air Service as soon as possible. Avro having developed a civilian / military transport version of the Lancaster, the York, the Department of Munitions and Supplies asked Victory Aircraft, in the fall of 1942, to manufacture fifty aircraft modified as required by Trans-Canada Air Lines. The latter, however, obtained the cancellation of the contract even before the end of the summer of 1943. The first transatlantic flights made by the Lancasters converted into airliners revealed a strong tendency towards icing. Trans-Canada Air Lines also realised that the York’s cabin could not be pressurised, a gap of importance for the postwar civilian market. The RCAF showed no more interest in the York. This being said, Victory Aircraft received permission to complete an aircraft. Given the priority given to Lancaster production, this York did not fly until November 1944.

May I permitted a brief digression? In August 1943, Eric James “Bill / William” Soulsby joined the staff of Victory Aircraft. It so happened that the new assistant manager had married, in June, Elizabeth Muriel Gregory “Elsie” MacGill – the first women in North America, if not the world to earn a master's degree in aeronautical engineering. Both of them had recently been forced out of their respective positions at CCF. The aforementioned Boyd, who had worked at CCF, knew both of them well. Indeed, one could argue that he was MacGill’s mentor. It was Boyd who gave her newly founded consulting business its first contract, some calculations for components of the Lancaster airliners. More importantly, MacGill later wrote a report on the suitability of the York for transatlantic flying. And yes, her conclusions were that the aircraft was not suitable.

The end of the Second World War and the massive cuts in aeronautical production did not mean the end of Victory Aircraft. A new phase of its history actually began in 1943 with the visit of the British Roy Hardy “Dobbie” Dobson in Canada. The Chief Executive Officer of Avro was so impressed by the Malton plant that he recommended to his superiors and colleagues that money be invested in it once the conflict was over.

In the spring of 1945, Avro began negotiations to buy the Malton plant, even though government restrictions prohibited any outflow of capital from the United Kingdom. Anxious to get rid of state companies involved in weapons production, Howe, then Minister of Reconstruction and of Munitions and Supplies, saw no objection to this sale project. The cancellation of the production contracts of the Avro Lancaster and Lincoln heavy bombers, in May and August, were, however, a heavy blow to Victory Aircraft’s activities.

Much to Howe’s surprise, Dobson continued the negotiations but said that Avro only wanted to rent part of the plant. The counter-offer of the minister surprised the British businessman. Half of Avro’s profits would be used to pay the rent, said Howe. This being said, if there was no profit, Avro would not have to pay a rent. Dobson rented the entire factory. Howe had gotten what he wanted, maintaining state control despite privatisation. The news became public in July 1945.

Despite this happy conclusion, the question of funding remained urgent. The new company needed money. Unable to take so much as a shilling out of the United Kingdom, Dobson got a basic advance from the federal government. At least one Canadian bank also agreed to support the project. Officially founded in September 1945, A.V. Roe Canada Limited took control of the Victory Aircraft plant in December. Dobson was president of the company. The saga of one of the most famous Canadian aircraft manufacturers began, but that’s another story.

I wish to thank all the people who provided information. Any mistake contained in this article is my fault, not theirs.

![A block of photographs showing some of the people involved in the bombing of beluga whales in the estuary and gulf of the St. Lawrence River. Anon., “La chasse aux marsouins [sic]. » Le Devoir, 15 August 1929, 6.](/sites/default/files/styles/thumbnail_7/public/2024-09/Le%20Devoir%2015%20aout%201929%20page%206.jpg?h=584f1d27&itok=TppdLItg)

![Peter Müller at the controls [sic] of the Pedroplan, Berlin, Germany, March 1931. Anon., “Cologne contre Marseille – Le mystère du ‘Pédroplan.’ [sic]” Les Ailes, 2 April 1931, 14.](/sites/default/files/styles/thumbnail_7/public/2021-04/Les%20Ailes%202%20avril%201931%20version%20big.jpg?h=eafd0ed4&itok=WnBZ5gMf)

![One of the first de Havilland Canada Chipmunk imported to the United Kingdom. Anon., “De Havilland [Canada] DHC-1 ‘Chipmunk.’” Aviation Magazine, 1 January 1951, cover.](/sites/default/files/styles/thumbnail_7/public/2021-01/Aviation%20magazine%201er%20janvier%201951%20version%202.jpg?h=2f876e0f&itok=DM4JHe5C)