Lithium-Ion batteries in Canada: Documenting a technological revolution

Those of us old enough to remember the world of twenty or thirty years ago have witnessed the changes brought by the steady improvement of lithium-ion (Li-ion) batteries. The little cells that once powered laptops and cellphones now challenge the world’s reliance on fossil fuels for transportation. The Canada Science and Technology Museum is documenting this process by collecting and documenting artifacts that represent Canada’s contribution to this evolving technology.

As the adoption of electric vehicles (EVs) drives demand for Li-ion cells dramatically upward, countries around the world race to mine battery minerals, to refine and process those minerals into battery materials, to manufacture battery cells, and to incorporate those cells into finished products. Researchers work to improve current technology and to develop the next generation of batteries.

Canada has important advantages in this global transition: its economic focus on resource extraction and processing has produced dozens of battery material projects. It has many technology companies that manufacture battery packs and electric vehicles. Its auto parts suppliers organize and promote battery production as their sector turns towards electric vehicles. Abundant electricity from nuclear and hydro attracts businesses working towards carbon neutrality. Though not often recognized, the groundwork for this shift has been laid by a Canadian history of battery production and research.

Before the invention of current-generation Li-ion cells, Moli Energy, based in Maple Ridge, BC, developed and manufactured the world’s first mass produced rechargeable lithium metal cell, the “molicel,” beginning in the mid 1980s. The company grew from a partnership between mining engineer and entrepreneur Norman Keevil, seeking a market for the molybdenum produced in BC copper mines, and UBC physicist Rudolph (“Rudi”) Heering, whose research group developed a method for using molybdenum as a cathode material in a rechargeable battery.

Moli Energy opened its factory in 1987—a remarkable achievement as it had to develop production techniques essentially from scratch. Eventually, the company fell victim to a common flaw in early lithium-metal cells: a tendency, under rare circumstances, to short circuit and catch fire. The company suffered a battery recall in 1992, after which it pivoted to the Li-ion cell. The research laboratory still thrives in Maple Ridge as part of the Taiwan-based Moli E-One Energy Corp.

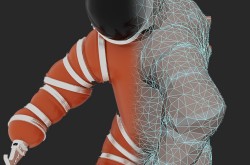

A second centre for Canadian battery development is Hydro-Québec’s research division, part of a major legacy of electric vehicle research and development. In the early 1990s, the division commercialized and manufactured the Lithium Metal Polymer (LMP) cell, a solid-state rechargeable lithium battery developed by French chemist Michel Armand. Solid-state batteries address the short-circuiting problem of the lithium metal battery.

In 2002, Avestor, a partially-owned subsidiary of Hydro-Québec, commissioned the world’s first factory to mass-manufacture LMP batteries. Commercial development of the technology has been challenging but continues to this day. The current generation of LMP batteries is manufactured in Quebec and France by Blue Solutions, a subsidiary of the French conglomerate Bolloré group. Hydro-Québec’s cutting-edge research into solid state battery technology continues at its Centre of Excellence outside of Montreal.

As Canada seeks to build its battery supply chain, many of the experts leading the process worked at Moli Energy or at Hydro-Québec’s research centre or its battery producing subsidiaries. For example, the celebrated Dalhousie laboratory of Jeff Dahn, formerly Director of Research at Moli Energy, collaborates closely with Tesla on battery development. In the coming months, the curators at Ingenium will seek to collect and preserve the material evidence of such work so that future researchers can study this moment in Canada’s technological history.

Enjoying the Ingenium Channel? Help us improve your experience with a short survey!