Variable Pitch Propeller

This article was originally written and submitted as part of a Canada 150 Project, the Innovation Storybook, to crowdsource stories of Canadian innovation with partners across Canada. The content has since been migrated to Ingenium’s Channel, a digital hub featuring curated content related to science, technology and innovation.

The variable pitch propeller gave pilots a new measure of control over their aircraft’s performance.

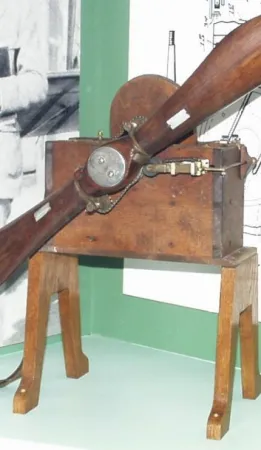

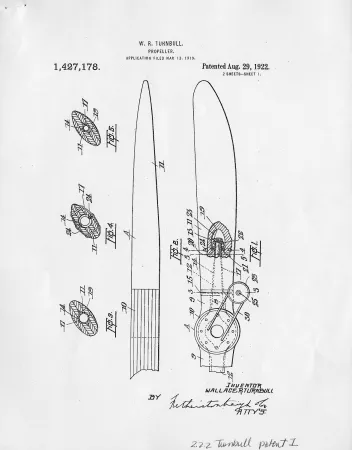

The variable pitch propeller took flying controls to a new level. Propellers used on early airplanes had blades that were fixed at a specific angle. Variable pitch propellers turned this idea upside down by allowing pilots to adjust blade angle or pitch during flight. Blade pitch affects the propeller’s thrust and is thus similar to gearing in a car or bicycle. Low or fine pitch optimizes take off and climbing, while high or coarse pitch maximizes high-speed flight. Various engineers pursued the idea of the variable pitch propeller—including one Canadian, W. Rupert Turnbull, a New Brunswick engineer. Turnbull began work on variable pitch propellers during the First World War, but his first mechanical designs were failures. After the war, he turned to electrical controls that provided finer blade-pitch adjustments. Turnbull’s electrical mechanism was first tested on a Royal Canadian Air Force Avro 504K trainer on June 29, 1927, at Camp Borden, Ontario. Unable to attract investors, Turnbull sold his propeller patents in 1929. They were eventually acquired by Curtiss-Wright Corporation, an American company that used Turnbull’s invention on many of its aircraft.

W. Rupert Turnbull, who designed one of the first successful variable pitch propellers, also designed Canada’s first wind tunnel.

![A block of photographs showing some of the people involved in the bombing of beluga whales in the estuary and gulf of the St. Lawrence River. Anon., “La chasse aux marsouins [sic]. » Le Devoir, 15 August 1929, 6.](/sites/default/files/styles/thumbnail_7/public/2024-09/Le%20Devoir%2015%20aout%201929%20page%206.jpg?h=584f1d27&itok=TppdLItg)