Donkeys and Snow Chutes at Summit Lake, B.C.

This article was originally written and submitted as part of a Canada 150 Project, the Innovation Storybook, to crowdsource stories of Canadian innovation with partners across Canada. The content has since been migrated to Ingenium’s Channel, a digital hub featuring curated content related to science, technology and innovation.

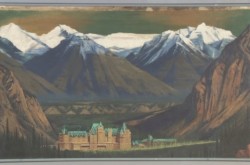

Summit Lake is located midway between Nakusp on the Upper Arrow Lake, and Rosebery on Slocan Lake, in the West Kootenay of southern British Columbia.

In 1908, when George Robinson was building the Summit Lake Lumber Company mill there, conditions were ideal for the undertaking! There was flat land for a townsite and mill. The Nakusp and Slocan Railway ran along the lakeshore. The lake itself would transport logs to the mill. It was expected they would cut over one hundred million feet of standing timber. A double mill was built to produce telegraph poles on one side, and ties on the other. Several innovations unique to the time were used in logging operations at Summit Lake.

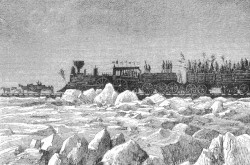

One was high lead yarding. Once a tree is cut, it must be yarded, or transported, to a central landing. High lead yarding uses the lifting power of high lines to move logs. A specially chosen spar tree would be climbed by a logger, who limbed and topped it – a hazardous undertaking indeed! Then blocks and cables, to be used in moving the logs, were attached to the spar. Power was provided by a steam donkey, a machine with straps, cables, and winches. The steam donkey could move itself around from place to place, as needed. High lead logging was common at the West Coast, but not inland. In the West Kootenay of those days, Summit Lake was only one of two logging shows that used the high lead system.

Once at the landing, logs still needed to be moved to the lake, where they would be towed to the mill. Initially, the loggers laid down rails of small logs to the water. Horses pulled logs on cars with hollow wheels, which could run on the wooden rails. This system had a few problems! Sometimes the loaded car got going too fast, and ran into the horses. Sometimes the cars jumped right off the rails. This led to the laying of steel rails. Logs were loaded onto cars with brakes, which coasted down to the water. Horses pulled the empty cars back up the slope.

Chutes were used to carry logs down steeper mountainsides to the lake. They usually would be made of greased wood. In the winter, Summit Lake could receive up to three metres of snow. Early loggers used the white stuff to make a unique snow chute for log transport. First, they tramped down a path to the water. Then, on a mild day, they would lead a horse pulling a log down the path. When the path froze, they could shoot logs down. As snow continued to fall, the walls of the chute rose higher and higher. The heat of friction from a log sliding down would melt the chute; then it would freeze again.

The Summit Lake mill burned in March 1920. A lucrative pole business was established on the site in 1921. This business once sent a 102-foot flagpole out, on three railcars, on its way to England!

In 1925, a fierce forest fire burned everything at Summit Lake except for the Railway station. The steel rails stayed there until being torn up for scrap metal during World War II.