My phone is blowing up! Dissecting technological artifacts for conservation treatment

Conservators have a unique relationship with museum artifacts. We are the professionals who work intimately with artifacts to ensure their preservation and make them accessible for use and interpretation. In a technological collection like Ingenium’s, this means we often need to partially disassemble artifacts while working to preserve an artifact. These unique opportunities to see what makes a phone ring, or what makes a clock tick, are carried out with care, ethical guidance, and a large amount of joy! In this article, we will look at a few treatment case studies that demonstrate when and why conservators take technological artifacts apart.

Why would we need to partially disassemble something?

We open up artifacts to check the condition inside and ensure there are no hidden problems. This part of a task is called a condition assessment. This assessment allows conservators to investigate what state the various components and materials are in, due to age or use. The information gathered helps to determine if the artifact is actively deteriorating, or in a stable state. In turn, this allows conservators to make better-informed decisions about its care, such as ideal storage conditions, housing, or the length and condition of display that are possible. Conservators will often carry out and record condition assessments on the same artifacts many times over the life of an artifact, allowing several generations of conservators to observe the stability of the materials over time. With numerous recorded assessments, we can learn a lot about the materials the artifact is made of, and the success of previous treatments, usage, display, handling or storage methods.

Conservators also open up artifacts to stabilize or clean the materials inside; this is part of a conservation treatment. Such treatments are often completed in advance of display or loan to another institution. When conservators do this type of work, they apply ethical guidelines and aim to affect the least amount of permanent change to an artifact. A lot of notes and pictures are taken, to document the entire treatment process and ensure that the artifact’s state is only minimally altered and completely accountable. With technological artifacts, the interior components are just as important as the exterior and need to be cared for; the inside is often where the nuts and bolts, wires, and circuits of a technological artifact are found. When treating these kinds of artifacts, we need to carefully disassemble them to work on the interior, and use the pictures, notes, and reference materials — such as patents or technical manuals we have gathered — to guide the reassembly.

Northern Electric Rotary Princess Phone

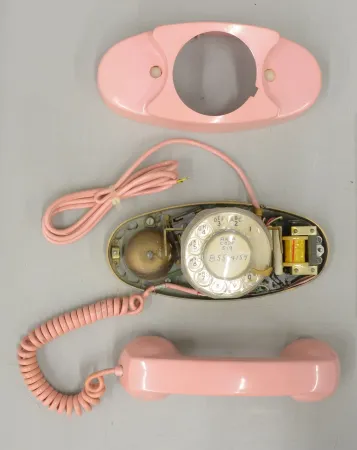

You may have seen this rotary Princess phone (c 1965) on display in the Sound by Design gallery at the Canada Science and Technology Museum. It was treated to prepare it for display. Part of this treatment involved carrying out a thorough condition assessment. The exterior plastic housing of this phone and handset represent only a small fraction of the materials and components that make it a functioning whole.

This Princess phone (circa 1965) in the conservation lab after treatment (Artifact No. 1999.0151).

Under the pink plastic casing of this Princess desk phone are a variety of materials and components: a copper alloy bell, polyvinyl chloride (PVC) wiring, plated iron alloy brackets, the rotary mechanism for the brackets, and a multitude of soldered points. All of these materials have very different properties and deteriorate in different ways, sometimes negatively affecting each other in the process. The PVC wiring may become tacky, the plastic may crack or crumble, and the copper alloy may tarnish or corrode, all in proximity to each other.

After carefully checking if and how the phone could be safely taken apart, the screws holding the case and dial cover were removed, and the parts lifted off. The dial cover was further disassembled by carefully prying and twisting the components as necessary. This provided enough room for me to access the internal parts. Using small probes and magnification, I was able to determine that all the interior components of this phone were stable by examining the surface features, surface texture, colour, cohesiveness, and hardness of each component. It proved to be an excellent candidate for long-term display.

Image gallery

Western Electric explosion proof mine phone

Sometimes conservation treatment presents a unique opportunity to see the interior of rare or complex artifacts that normally could not be disassembled easily. This Western Electric explosion-proof mine phone (circa 1951) is one of those artifacts. The thick, steel housing makes it very heavy, so it is not often handled or retrieved from storage, and the face of the phone is difficult to remove. While it was in the Ingenium Conservation Lab, the opportunity presented itself to document the interior components and observe and record features that would otherwise remain hidden. The phone was designed to prevent explosions deep in a mine, so all of the components that could generate heat or sparks are located very securely inside the metal housing. The face of the phone screws on like a giant twist cap, which provides a good seal. Once opened, you can see many of the parts that make this phone work, and how sturdy and well secured the components are.

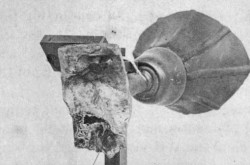

The cover has been removed from the explosion-proof phone, exposing interior components (Artifact no. 1975.0197).

The complete explosion-proof phone (Artifact no. 1975.0197).

Once opened, the interior was well documented through a series of detailed photographs, and thorough notes were made on the condition of the materials and parts. Because the face seal on this phone was so effective and intact, I did not have to clean any accumulated dust or debris from the interior. The seal also maintained excellent environmental conditions inside the phone. That means that the humidity remained very stable over time, and exterior temperature changes were minimized on the inside. It also meant no liquids or pollutants, such as dust, could enter the housing. Because of this, the kind of corrosion and tarnish you would expect to form over 70 years was not present.

The rotary dial of the explosion-proof phone, disassembled for treatment (Artifact no. 1975.0197).

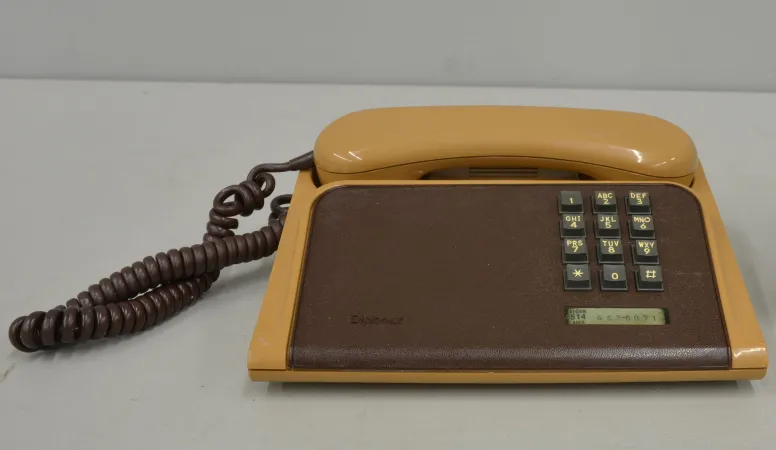

Northern Telecom Diplomat desk phone

Often artifacts are collected in an ‘as is’ state. This means the museum receives them in the condition in which they were last used — fingerprints and all! This can be great because it allows curators to show evidence and stories about the users, the artifact’s place in society, the life of the artifact, and the production and design of the artifact itself. Where possible, conservators leave residues in place. However, sometimes they are detrimental to the artifact, hazardous, or can attract pests which can cause damage to other artifacts around it. As you can see, this well-loved Northern Telecom Diplomat desk phone (circa 1981) had a heavily soiled keypad. This was likely a mix of oils from the user’s hands, and residues from an unfortunate coffee incident in the office (it happens to the best of us!). In this case, these residual fluids become encrusted with dust over time. Dust attracts moisture to surfaces and can sometimes lead to mold growth, or act as a starting point for deterioration, both of which would cause the condition of the plastic phone to change over time. So, the grime had to go!

A Diplomat desk phone, soiled from use (Artifact no. 1999.0153).

To remove the grime from this phone, partial disassembly was ideal to get at all surfaces. I determined that it would be possible to do this in a safe manner, meaning the materials on the exterior were able to be handled and removed, and the method of disassembly could be determined. Disassembly also made the cleaning process safer for the artifact. Since the surfaces were slightly soft and glossy, it would be better to use a small amount of detergent and water instead of hard tools that may scratch the surfaces. Opening the artifact not only ensured that hidden grime was removed, it also allowed the me to better control and remove any excess liquid quickly. Water left inside an artifact of this type could cause metal components to rust, or encourage mold growth. After cleaning with an aqueous solution, the phone was left open for some time to allow the interior to fully dry.

Image gallery

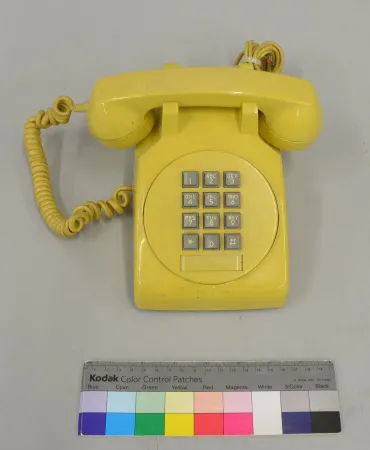

Northern Electric Touchpad Phone

Sometimes conservators want to open an artifact to clean or assess the interior, but it is not possible without damaging it. Much like doctors, we have an ethical guideline to ‘do no harm.’ This yellow Northern Electric desk phone (circa 1968) was partially disassembled for assessment and treatment. It would have been ideal if the keyplate could have been removed, exposing the connected components below. However, after careful examination, it proved more difficult and riskier than necessary for the amount of treatment required to prepare it for safe display. The risk being that further disassembly could result in irreparable change to the artifact, such as scratches, broken interior components, or damaged solder points.

Often when faced with such a dilemma — or if doing exploratory work on an artifact for which methods of entry or disassembly are not apparent — conservators will use other tools to look inside the artifact, such as blueprints or patent drawings for reference, a borescope, radiography, or CT scanning (in rare cases). In this case, dental mirrors were used to see parts within the covered sections of the interior, and no other tools were required. Once opened, the interior was carefully assessed, documented, and then cleaned using a vacuum with a very small attachment and suction control. I then used both dry and slightly damp swabs to lift all the dust out. The ringers and other brass components were cleaned with ethanol to remove dusty grease. The exterior of the phone was wiped down with a detergent and water, and debris was removed from cracks and crevices using dental tools under magnification.

Image gallery

Everyday artifacts like telephones are extraordinary when you dig deeper, as are most artifacts in the Ingenium collection! The next time you are at one of our museums or browsing the collection online, consider what the interior of the artifact you are looking at might be.

Conservators at Ingenium work with and treat artifacts from all sorts of technological, industrial, and scientific backgrounds with the goal to preserve them and make them more accessible to the public and for research. Many of the artifacts in this article can be found in the Sound by Design exhibit at the Canada Science and Technology Museum.

Have more questions about the conservation of technological artifacts? Connect with the Ingenium conservation team on Twitter @SciTechPreserv