Maple Sap Spout

This article was originally written and submitted as part of a Canada 150 Project, the Innovation Storybook, to crowdsource stories of Canadian innovation with partners across Canada. The content has since been migrated to Ingenium’s Channel, a digital hub featuring curated content related to science, technology and innovation.

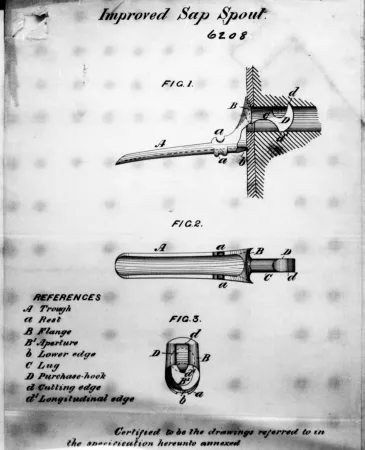

Today’s Canadian maple syrup producers use modern vacuum tapping systems to increase the amount of sap produced by maple trees, but as late as the 1960s, the majority of producers practiced what were essentially centuries-old techniques. Long before Europeans arrived, Aboriginal peoples in the regions of what are now Ontario, Quebec, and the Maritimes collected and boiled sap from maple trees. Sap was collected in bark containers using a hollow reed that was inserted into a diagonal cut in the trunk. The sap was added to larger containers, into which heated stones were dropped to boil the sap down to a dark, sweet syrup. Europeans essentially emulated this process by using tin pails, boilers and spouts. By 1876, Hiram Addison Lawrence of East Farnham, in Quebec’s Eastern Townships, felt sap-tapping practices were long overdue for a change. Lawrence’s patent application notes that the commonly used spouts were “in many points very defective in their working, and even absolutely injurious to the tree.” Sap was often lost from leakage around the spout, while frozen sap could force the spouts right out of the tree, and often the force required to insert the spouts often loosened the bark, inviting long-term decay. Lawrence claimed his spout corrected all of the stated defects. A hooked end of the spout was inserted into the hole until a flange at the base of the channel came into contact with the bark. The weight of the pail on the spout’s channel caused the hook to dig in, while the flange prevented leakage.

Numerous competing sap spout patents were filed around the end of the 19th century, including Lawrence’s own 1880 update, indicating that maple producers had like-minded ideas for advancing the quality and quantity of production.