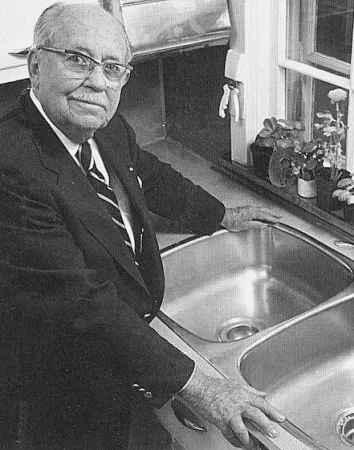

Even the Kitchen Sink

This article was originally written and submitted as part of a Canada 150 Project, the Innovation Storybook, to crowdsource stories of Canadian innovation with partners across Canada. The content has since been migrated to Ingenium’s Channel, a digital hub featuring curated content related to science, technology and innovation.

Pre-1948, the typical kitchen sink was made of cast-iron coated in baked enamel that chipped and stained easily. Harry Galley, who had been in the nickel business for a couple of decades, knew there had to be a better option. Stainless steel seemed to fill the bill: lightweight, durable and easy to clean. Other designers had created one-of-a-kind sinks from stainless, but no one had successfully found a method of mass production. Galley discovered a way of using newly improved tooling techniques to manufacture fine quality sinks that would meet consumer demand – which was immediate and overwhelming! Today, kitchen sinks are among the top end-uses for stainless steel with about 30 million kilograms of nickel (the source of stainless steel) used to make new sinks each year.