Waterloo project wins top honours in Dyson competition

This article was originally written and submitted as part of a Canada 150 Project, the Innovation Storybook, to crowdsource stories of Canadian innovation with partners across Canada. The content has since been migrated to Ingenium’s Channel, a digital hub featuring curated content related to science, technology and innovation.

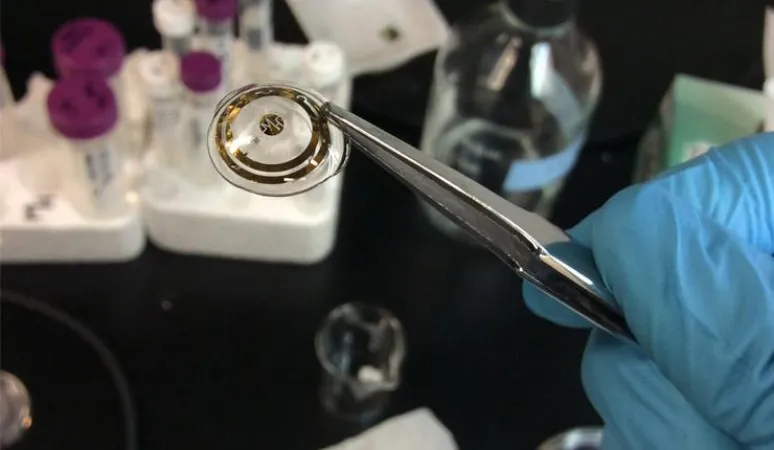

James Dyson says Medella Health’s smart contact lens shows how good design and engineering can improve lives.

A smart contact lens that monitors glucose levels captured one of two international runner-up awards in the 2016 James Dyson Award competition, the third University of Waterloo student project to win a top prize in three years.

Medella Health, co-founded in 2013 by Huayi Gao, a Waterloo nanotechnology engineering graduate, Waterloo science graduate Maarij Baig, and Harry Gandhi, who studied science and business at Waterloo, is developing a contact lens to continuously monitor glucose levels in the tear film for diabetes management. The information collected is sent to a user’s mobile phone so the individual can better manage glucose levels throughout the day.

In judging the Waterloo project, James Dyson, the British inventor of the bagless Dyson vacuum cleaner, said the smart contact lens has the potential to help millions of people with diabetes by removing the need to invasively test blood. “It really shows the way that good design and engineering can improve lives,” said Dyson, for whom the award is named. “I was particularly impressed at how the team condensed the technology into such a small format without compromising the product.”

Medella Health, which operates out of the University’s Velocity Garage in downtown Kitchener, will receive $7,500 to further develop its product in addition to the $4,000 the company secured earlier this year as the national winner in Canada.

“By using the money we were awarded as the national winner in Canada and now as international runners up we will further optimize the technology,” said Gandhi.

Medella Health currently includes 15 experts in nanotechnology, health IT, micro-electronics and micro-fabrication. The company hopes to begin clinical testing of the smart contact lens next year and eventually expand it to monitor other biomarkers, ranging from heart disease to stress management.

Gao, who began working on the smart contact lens as a fourth-year nanotechnology engineering design project, said Medella Health is proud to be part of the University’s entrepreneurial ecosystem.

“We are incredibly lucky to have access to the expertise and facilities of three world class laboratories within the University of Waterloo – the Waterloo Institute for Nanotechnology, Centre for Contact Lens Research and the Centre for Intelligent Antenna and Radio Systems,” said Gao. “Velocity also played a crucial role by supporting Medella with free space, industry veterans and technology gurus.”

Open to university students and recent alumni in the fields of product design, industrial design and engineering, the James Dyson Award is an international challenge to design something that solves a problem.

University of Waterloo teams have taken top honours in the past two competitions. Last year, Voltera won first-place overall with its desktop sized circuit board printer that turns design files into prototype boards in minutes. In 2014, Suncayr was an international runner up with its colour changing marker that alerts a user when sunscreen is no longer providing protection.