Robotic technologies at nuclear facilities

This article was originally written and submitted as part of a Canada 150 Project, the Innovation Storybook, to crowdsource stories of Canadian innovation with partners across Canada. The content has since been migrated to Ingenium’s Channel, a digital hub featuring curated content related to science, technology and innovation.

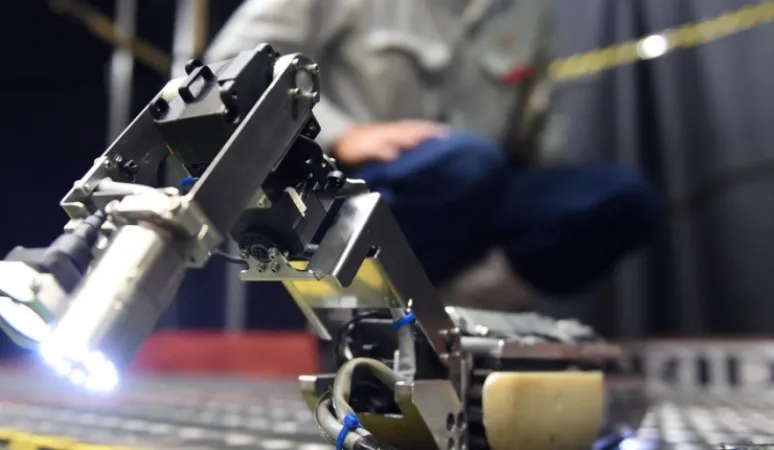

Robotic technologies are used in a wide range of sectors and applications, from automotive assembly lines to space exploration. Not only do robots allow processes to be automated, they also provide safety benefits by performing tasks that would otherwise be highly dangerous or complex for humans to conduct using conventional means.

For instance, robots can perform tasks in environments with extreme temperatures, pressures or radiation fields, and inspect equipment in areas that are difficult to access. As a result, robotic technologies have become an indispensable resource across a wide spectrum of fields, including Canada’s nuclear industry.

Applications in Canada include robots that aid in nuclear power plant safety inspections, fuel transfers and removals, repairs and long-term maintenance. This has increased nuclear safety by giving licensees the ability “…to reduce worker dose and inspect parts previously considered inaccessible,” according to Greg Lamarre, Director of the Systems Engineering Division at the Canadian Nuclear Safety Commission.

Robots are designed to safely do what humans could not, and these technologies will continue to play a pivotal role in the waste management and decommissioning efforts in Canada’s nuclear sector.